What do manufacturing companies need to implement digital twins in their supply chain? And what are the pitfalls during implementation?

In this three-part blog series, we look at the use of digital twins in the supply chain of manufacturing companies, based on a survey of selected companies conducted by the authors. In the first part of the series, we used the survey results to show how companies evaluate digital twins in terms of relevance, potential, and goals. This article presents the technical foundations required for the use of digital twins and describes the hurdles that the survey participants experienced during concept development and implementation.

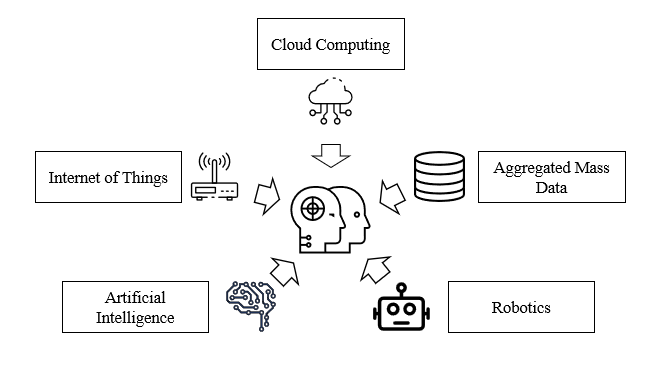

The Technological Foundation of a Digital Twin

A digital twin is a technological concept that plays to its full strengths when essential technologies are in place:

- Cloud Computing – decentralized data storage and analysis

- Big Data – aggregation of mass data and data streams

- Robotics – use of non-human work force

- Artificial Intelligence – recognition, evaluation, and interpretation of unknown scenarios

- Sensor Technology (Internet of Things – IoT) – real-time recording of statuses and locations

Each of these technologies is a project field in its own right. Companies need a certain level of maturity in each discipline if they want to implement digital twins. It is important not to become a technology company, but to precisely find the level of maturity for your own organization that is needed for the purpose of digital twins.

The survey results show four areas where companies are struggling with implementation hurdles:

- IT architecture and management

- Organization

- Process management and integration

- Financial hurdles

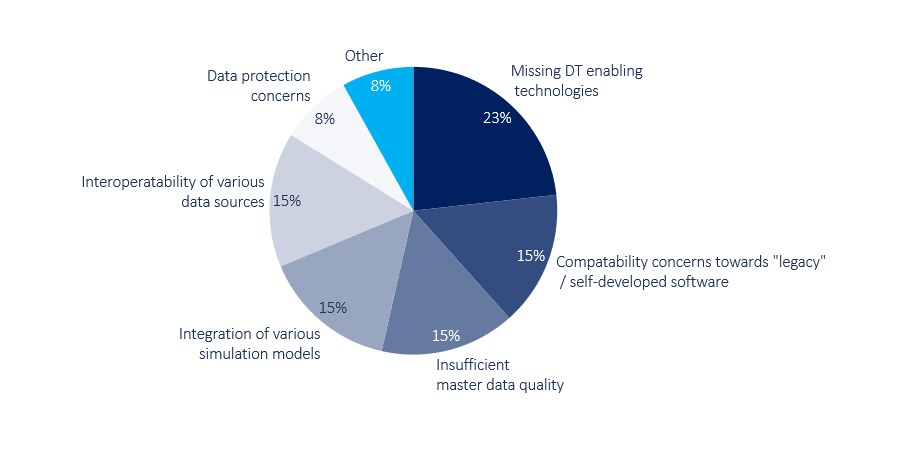

Hurdles in IT Architecture and Management

Companies see the lack or an insufficient foundation of the necessary technologies as a significant IT-related hurdle (23%). In their view, the companies surveyed have not yet reached the required level of maturity in the area of artificial intelligence, big data and other technologies.

Second place (15%) is occupied by various challenges, such as dealing with so-called “legacy” IT architecture, e.g., SAP ECC systems that do not always support modern technologies out of the box. Master data quality in need of improvement as a classic among the general transformation challenges is also found here. The companies also dealt with the question of how to handle different data sources that arise in a more complex IT architecture and must be merged to supply the digital twin. Which simulation methodology ultimately best suits the company is also a headache.

One challenge that we regularly observe in projects is mentioned relatively rarely by the companies surveyed (Other 8%): trying things out instead of planning. Instead of discussing a concept down to the smallest detail, the learning curve is steeper if an initial prototype is developed promptly. This is advisable to make the abstract construct of the digital twin more tangible for stakeholders.

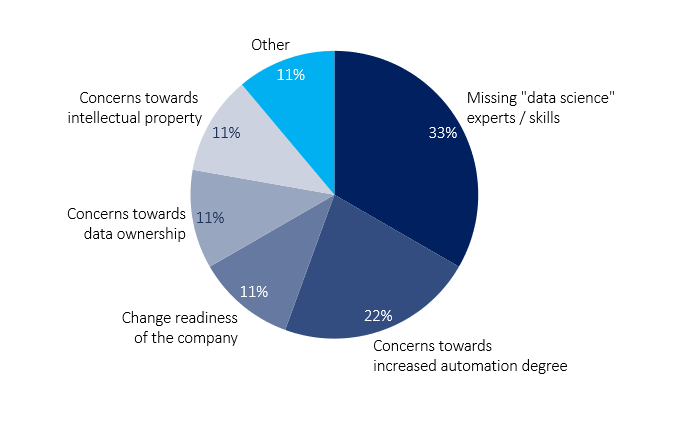

Organizational Hurdles

The companies surveyed cited particularly the lack of data science experts as an organizational hurdle (33%). They are the ones who build, operate, and further develop technological foundations in-house. Here, the companies confirm the difficulty of building up qualified personnel in the data science area. This raises the question of whether a company must build up these skills itself or whether they can also be procured externally, tailored to its specific needs. The topic of “make-or-buy” decisions will be part of the third post in this blog series.

The digital twin relies heavily on automation. While process events are always transparent in manual execution, this is not always directly the case in an automated system with process steps that run automatically and quickly. This can give rise to reservations about automated processes. In the survey of companies, this concern takes second place (22%), supplemented by the need to proactively involve and inform the workforce in such projects (11%).

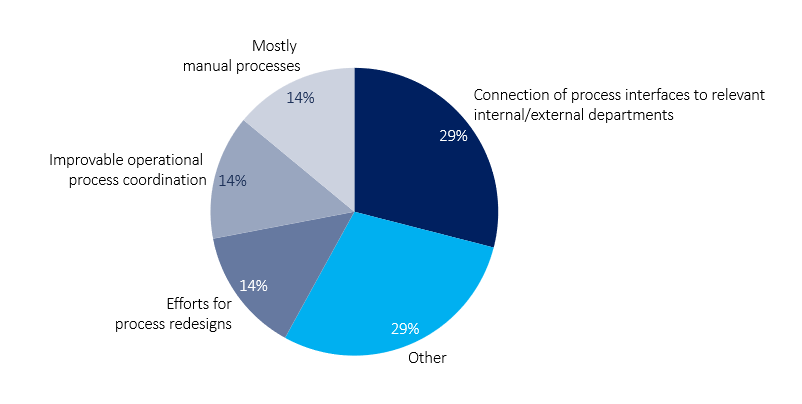

Process Management and Integration Hurdles

The survey revealed that in all cases a digital twin affects the process areas of production, logistics, and research & development. In addition, there is often direct integration into procurement, while integration into sales is rarely observed.

The companies surveyed see the challenge of integrating the digital twin into the existing processes and designing the process interfaces to other, internal process areas (29%). This is particularly true if external partners, e.g., for procurement, are to be integrated. In addition, a process interface may no longer be sufficient to exploit the possibilities of the digital twin. The process itself may have to be changed for this purpose.

With the same frequency (29% of all mentions), individual implementation hurdles are named, which can be summarized in two points. Concluding the correct assumptions from the evaluated data and transferring the result into the process flow is perceived as difficult. As a second aspect, the companies surveyed emphasized that process documentation first had to be created to better understand their own processes and the relevant process interfaces. However, as one company explicitly confirmed, this preliminary work alone can already identify initial potential for improvement.

Financial Hurdles

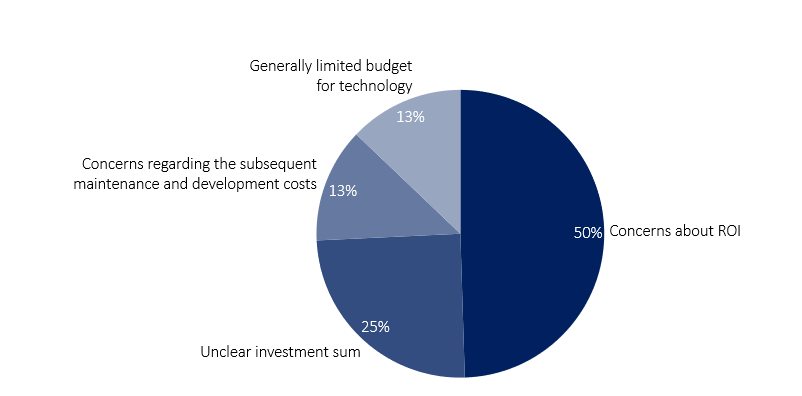

The answers are very clear when it comes to the question of what monetary added value the digital twin will generate after go-live. 50% of all companies surveyed report difficulties in reporting the return on investment (ROI). This can also be explained by the digital twin’s high degree of integration. Many technologies are used, several process areas are integrated with each other. For many companies, this means a new level of maturity, which is difficult to evaluate for ROI due to a lack of previous experience.

Complemented by the uncertainty regarding the necessary investment (25%), this creates a significant implementation hurdle that can lead to the required budgets not being released or only being released hesitantly at the strategic level.

Conclusion and Outlook

Our survey shows that companies have to overcome a variety of hurdles when implementing a digital twin. In addition to technological maturity and IT architecture, impacts on process management, a lack of data science competencies, an insufficient willingness to change on the part of the organization as well as an uncertain financial effort and ROI challenges are all factors that enterprises must overcome to turn digital twins into a competitive advantage for themselves.

In the third part of the blog series, we look at how the described hurdles can be addressed and removed and shed light on the “make-or-buy” tendency towards the digital twin.