On the one hand, manufacturing companies have high expectations of a digital supply chain twin; on the other hand, they face implementation hurdles. How can the realization succeed?

In the previous part two of our blog series on digital twins in the supply chain of manufacturing companies, we explained two exemplary use cases and described the challenges that companies face when implementing digital twins. But how can a digital twin be established in practice? In this third and final article in the series, we outline what to consider during implementation and how to avoid pitfalls.

The series of articles is based on a survey of selected manufacturing companies. When asked about the challenges in implementing digital twins, the respondents named hurdles in the categories of IT architecture, process management, organization, and finance (see Article 2). But what approach nevertheless enables implementation?

A successful approach comprises three steps:

- Goal definition and concept development

- Fit-gap analysis

- Development plan and business case

Step 1 – Goal Definition and Concept Development

The first step is ensuring a binding and concrete understanding of the future digital twin in the company. The primary objective is defining the benefits to be achieved. First and foremost, the company’s individual challenges are recorded, summarized, and compared with the technical possibilities of a digital twin. One goal is being able to say which challenges the digital twin can solve. Answering the question requires that one is already familiar with the basic function of the digital twin.

To ensure better dovetailing with strategic corporate goals, the strategic organizational level can already be included in this goal definition at the tactical level. The potentials and goals identified in the previous article can be used as a reference for defining the goals. The result is a goal agreement that describes the benefits the digital twin should achieve.

The goal agreement is the basis for the target picture of a digital twin to be created. The target picture shows how the digital twin is to be integrated into the operational and organizational structure. Among other things, it answers the following questions:

- Which process areas (e.g., production, logistics, procurement, etc.) are to be integrated?

- How intensive is the integration?

- How should external partners be integrated?

Implementation requirements can be derived from the finalized concept. They concern points such as the concrete IT architecture, process changes or changes in areas of responsibility. Once these questions have been answered with the involvement of the relevant contact persons, a target picture emerges.

Step 2 – Fit-Gap Analysis

The target picture is then compared with the actual state of the company. The as-is picture should include the three areas of processes, IT architecture, and organization. It is advisable not to examine all components of these areas in the sense of a comprehensive restructuring, but to focus specifically on the requirements for a digital twin.

For example, when examining the current IT architecture, the basic technological requirements of a digital twin (see Article 2 in the series) should be compared with the conditions in the company, i.e., the company’s maturity in the areas of artificial intelligence or big data needs to be checked. For the IT area, topics such as master data quality and the diversity of applications and interfaces are also relevant.

Regarding the processes area, it is interesting to highlight the degree of process maturity or the degree of automation to be able to implement real-time processing requirements, for example. At the organizational level, it can be examined where qualified personnel are lacking, or whether areas of responsibility should be cut differently in the future to accelerate information flows and decision-making.

The result of the as-is analysis is a clear overview of the gaps between the requirements for a digital twin and the company’s existing capabilities.

Step 3 – Development Plan and Business Case

With the gaps now known, a development plan to close the gaps can be created. The implementation effort for the measures in the development plan is ideally already estimated and weighted. It is conceivable to build up the development plan in phases to reach a new maturity plateau at certain intervals. These individual plateaus prepare the implementation of a digital twin. At the same time, however, they already have positive side effects on the company, such as a better understanding of processes and initial harmonization in the IT landscape.

50% of the companies we surveyed state that they find it difficult to evaluate the financial and time investment for implementing a digital twin. The fit-gap test and the quantified development plan provide the answer to the question of how long it will take and in what range the final investment sum will be.

The defined target picture allows a well-founded estimate of the quantifiable added value resulting from the digital twin. This in turn can be used to establish a business case.

Make or Buy?

Building a digital twin can mean a significant investment in several areas of a company. Therefore, the question of whether a company should build a digital twin itself or procure the simulation service is absolutely legitimate.

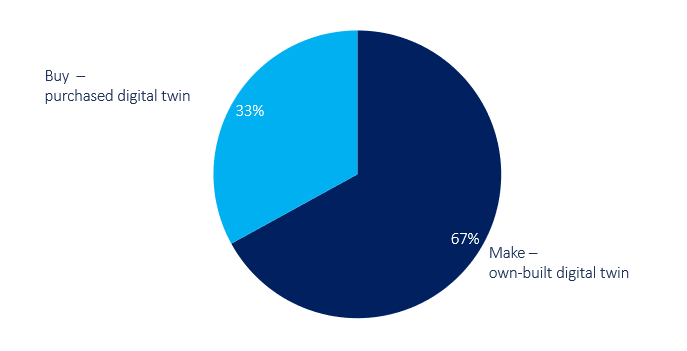

In our anonymous company survey, we therefore also asked the following question: “Do you think that digital twins are company-owned constructs in the long term, or that the service will be procured?”.

As Figure 1 shows, two-thirds of all companies surveyed say they will build a digital twin themselves. One third can imagine procuring the simulation service from digital twin providers.

Conclusion

As we have seen, it is possible to overcome the challenges of implementing a digital twin with a focused approach. Of course, the approach outlined here cannot reflect the full scope of such a project in its brevity. Nevertheless, it gives an impression of what a solution might look like.

Companies should basically consider three success factors in such a project:

- Bringing together the strategic level with the tactical/operational level for internal transparency

- Honest assessment of the company’s own capabilities regarding the necessary technology and process maturity levels and strategic alignment for a make-or-buy tendency

- Clear articulation of benefits and timely development of a simple prototype for a “look-and-feel” at all levels of the hierarchy on how benefits will be generated

In the three articles in this blog series, we have shed light on how companies evaluate the potential and goals of a digital twin, what implementation hurdles they see, what a possible project approach to implementation might look like, and what the make-or-buy tendencies are. We hope that this has given you some food for thought for your own corporate practice. Please feel free to contact us if you are interested in further details of the survey or practical experiences.