The versatile uses of digital twins have already been presented many times. But how can digital twins be implemented? What are the pitfalls? How do manufacturing companies evaluate digital twins in practice and in what application areas are they actually used? A survey among representatives of selected companies shows how the topic of digital twins presents itself in the practice of German manufacturing companies. In a three-part series of articles, we share the most important results.

What Is a Digital Twin?

There are numerous and quite different definitions of a digital twin. In this series of articles, we will refer to the following definition:

The digital twin is a multidimensional simulation of a real-world object or business process that is fed with data collected directly from the object or business process at defined intervals to generate optimal recommendations for action within a specified framework.

Based on this understanding, the next question is which role in the company will drive the conceptualization and subsequent realization of a digital twin. Roles at the strategic, tactical, or even operational level are conceivable. Due to the close integration of the digital twin with the process organization, including IT management, in our experience discussions on the concept and implementation ideally take place at the tactical and in some cases even at the operational level. This is where the people who can make statements on the process and organizational model and on the IT architecture are to be found. Nevertheless, early involvement of the strategic level, i.e., top management and the board of directors, is immensely important. Experience shows that it pays off at the latest in the transition from concept to implementation.

How Do Companies Evaluate the Potential, Goals, and Relevance of the Digital Twin?

For this blog series, we asked companies what goals, potential, relevance, implementation hurdles, and make-or-buy tendencies they see for digital twins in the supply chain. The companies surveyed are active in industrial manufacturing and belong to various sectors, from consumer goods and medical technology to the automotive industry. In this article, we provide insight into the identified potential, the goals as well as the relevance assessment by the companies.

Potential and Goals

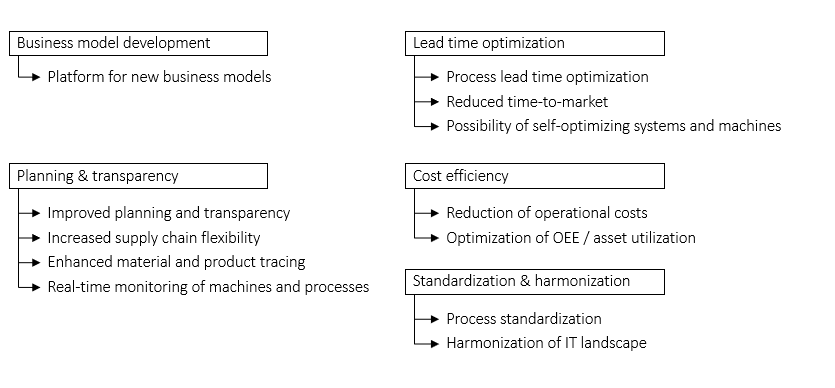

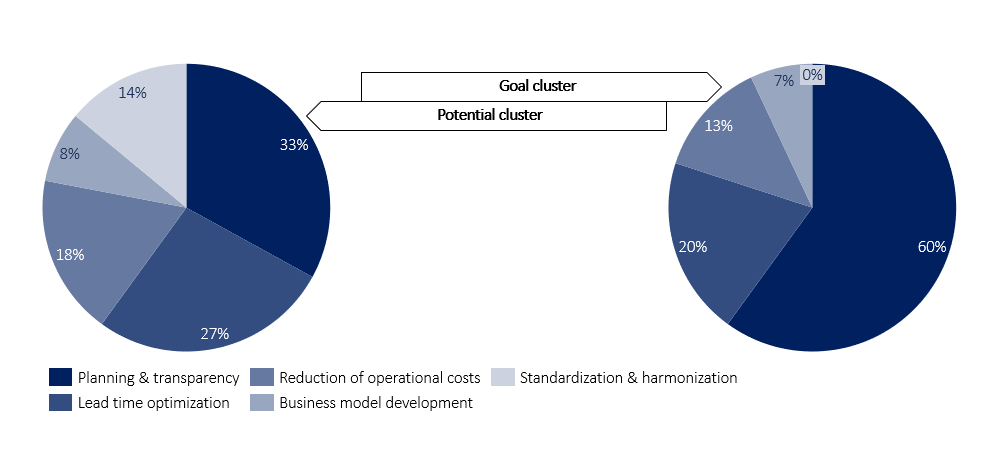

The survey participants could choose from various potentials and rate them as “very low” to “very high” (see Figure 1).

With 33% of all mentions, the companies surveyed most frequently named the potential “improve planning processes”, followed by process lead time optimization (27%) and operating cost reduction (18%).

As expected, the highlighted potentials are also reflected in the defined goals of the companies. The primary goal is to improve capabilities in planning and transparency, which accounts for 60% of all mentions. Only secondarily should a digital twin contribute to optimizing process lead time (20%) or reducing operational costs (13%).

Accordingly, the participating companies are responding to the ongoing global dynamic market situation and the fragility of their supply chains by considering what concrete competitive advantages a digital twin can bring. The main question is whether existing solutions for supply chain planning and decision support still meet market requirements at all.

We were surprised that creating a platform for digital business models was not mentioned once as a goal. This is because the data-focused approach of a digital twin offers exciting options for digital (additional) business models, e.g., the data broker.

Assessment of Relevance

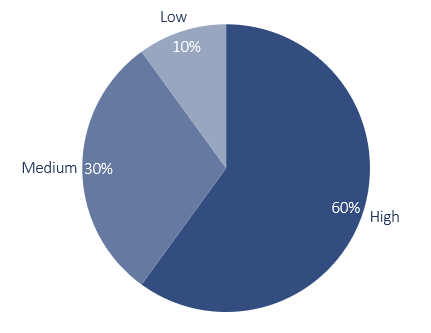

The question regarding the relevance of the topic “digital twin” shows a clear trend: 60% of the survey participants rate digital twins as highly relevant for the future of their own company. While just under a third (30%) of respondents still want to get their bearings, the majority of companies (60%) are open to concrete concepts and implementation projects.

What Kind of Digital Twins Are Companies Dealing with?

As part of the survey, the participating companies (anonymously) named two real use cases: a product twin and a plant twin.

The product twin replicates the anonymized machine characteristics of its physical counterpart in terms of condition, location, production parameters and environmental influences (heat, humidity, etc.). This not only enables the detection of impending failures (predictive maintenance), but also makes customers’ usage behavior more transparent. On the one hand, this supports the company’s own research and development department in the further development of future products. Secondly, it increases the sales department’s understanding of customer needs and challenges.

The plant twin is highly integrated into the process areas involved. This digital twin relies intensively on human-machine collaboration in the cyber-physical space. It maps not only individual machines, but also connected production plants. Adjacent process areas, such as intralogistics, procurement, and sales, are included in the simulation and decision-making process. In this way, production downtimes can be reduced, logistical supply optimized, and proactive customer information simplified. For the future, integrating several locations of the production network is being considered.

In these articles, our colleagues show what other possible applications and concept ideas there are for digital twins.

Conclusion and Outlook

The results of our survey show that the majority of companies see a high relevance of digital twins for themselves. Conceptual discussions and prototype developments are taking place to significantly optimize planning capabilities and increase transparency along the supply chain towards a proactive approach. Evaluating the global-dynamic developments faster, with less effort and more precisely and making better decisions is the goal of these initiatives.

In the upcoming blog article, we highlight necessary technological foundations as well as the implementation hurdles companies have experienced on the way to the digital twin.