What defines your production capacities? Is it the output of your production machine or the availability of skilled shop floor labour?

Why human skill sets become so important with increasing digitalization?

Even though the trend goes towards automation, robotics and digitalization many tasks in production still need to be performed by humans. Some steps remain manual and others are not yet automized. Machines must be set-up, maintenance tasks must be performed, equipment must be cleaned, and machines must be controlled. All of this requires different skill sets of employees working on shop floor level.

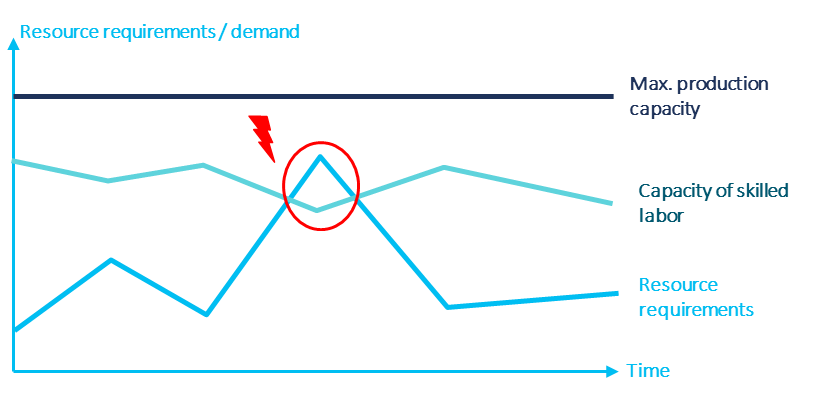

While some tasks are rather mechanical, others require IT and software related skills and know-how. The higher the degree of automation & digitalization the higher the requirements of various skill sets towards the employees. Consequently, the available production capacity is no longer defined by the output a production machine can perform. The available production capacity heavily relates to the availability of skilled labours to control the production machine. The availability of skilled labour is therefore a major constraint for the production plan and must be considered to ensure product availability and plan stability.

Why many companies struggle to account for skilled labour within their planning?

- First, the responsibility for shift and production planning is often separated within different organizations. While production planning is owned by supply chain management departments, the management of shifts and available employees is in responsibility of the shop floor of the local production site.

- Second, missing IT support to model but also to account for required and available skill sets. Some employees might be certified for all tasks and production machines; however, some others might only be trained for a specific set of tasks and machines. The combination of number of employees and available skill sets results in complex skill matrices which very often cannot be reflected in standard software solutions.

- Third, real time visibility at rescheduling is lacking with regards to availability and capacity of a specifically required skill set. Any short-term changes in the production plan directly impact the requirement of a specific skill-set. To evaluate if the production plan remains feasible, the availability of skilled labours must be considered at rescheduling. However, also here standard software solutions very often can not provide this visibility.

How to win the battle man vs. machine?

To account for the dependency of skilled labor and resource requirements, companies need to revise their current planning process and IT support. By integrating the human aspect and skill pool planning within creation of a feasible production plan, the planning performance can substantially be increased.

Integrated planning is a central lever to ensure:

- Reliability of shift planning by giving an outlook of required skills needed at a specific point of time at production

- Increase of plan adherence by reducing the need for fire-fighting and re-scheduling on shop floor due to unavailability of skilled labor

- Increase of product availability and decrease of lead times by stabilizing the production

“Give me a lever long enough and a fulcrum on which to place it, and I shall move the world” (Archimedes)

If you need support to enable integrated planning within your organization, feel free to contact us for process guidance – and our colleagues from Camelot ITLab for software solutions.

This article is part of a series. See the other articles:

Why productions plans get overruled by labor availability

Considering labor skills for a feasible production plan

More information about the CAMELOT solutions and service offerings: