You have done all the steps to create a feasible one-number-plan for production, aligned and digitized your supply chain organization, hired industry-proven production planners BUT still you are ending up with firefighting? Still you are rescheduling your plan in the short-term? Still you cannot meet planned customer service levels? Maybe you have not considered all relevant constraints to build up the optimal production plan. Read more about the influence of labor availability on production planning:

Why the perfect plan is not the perfect plan

Building up a feasible production plan is not an easy task. Lots of constraints need to be considered like resource availability, tool availability and components availability. And if it is all done, there will be countless stumbling stones on the way to the final product especially in the short-term horizon: machine break downs, missing components, quality issues, rush orders, … – just to name a few ones.

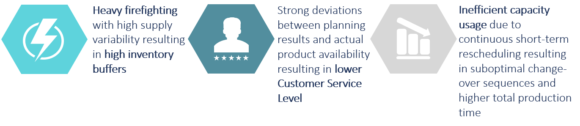

Figure 1: Shortcomings due to plan rescheduling

Figure 1: Shortcomings due to plan rescheduling

Often, missing skilled labor is named as a major stumbling stone and causes a lot of rescheduling of the perfect production plan. In fact, lots of companies are throwing their plan in the dust bin, in order to fully rework it based on labor constraints. Consequently, companies are suffering from this rescheduling as described in Fig.1.

Why is labor availability still such a big source for issues in the short-term horizon even if it is already considered e.g. in shift models of the available resource capacity?

- Even though companies are considering every complex detail of how to produce a specific product, they are often NOT considering the specific skills of their employees. Let us give you an example: Only a few employees are capable of doing complex tool changes on resources. Other employees can be used only for the assembly tasks and others can do actually both. The real skill pools of the employees are often not modeled in the optimal production plan – therefore the perfect plan won’t be the perfect plan.

- Even if you could model the skills of employees, it is necessary to correctly assign tasks and level the labor plan in order to not “waste” highly skilled labor for the simple tasks.

- Companies are lacking real-time visibility of rescheduling impacts of labor planning on production schedule and vice versa. Therefore, rescheduling impacts cannot be anticipated ending up in an endless cycle of adjustments bringing high volatility to your supply chain planning.

Considering all, the major issue is missing IT support to model complex employee skill pool scenarios but also integrating them in planning.

You are experiencing similar issues? Stay tuned for our next blog post on how to close the gap to a feasible production plan by considering employee skills at production planning.

This article is part of a series. See the other articles:

Man vs. machine – who controls your production?

Considering labor skills for a feasible production plan

More information about the CAMELOT solutions and service offerings: