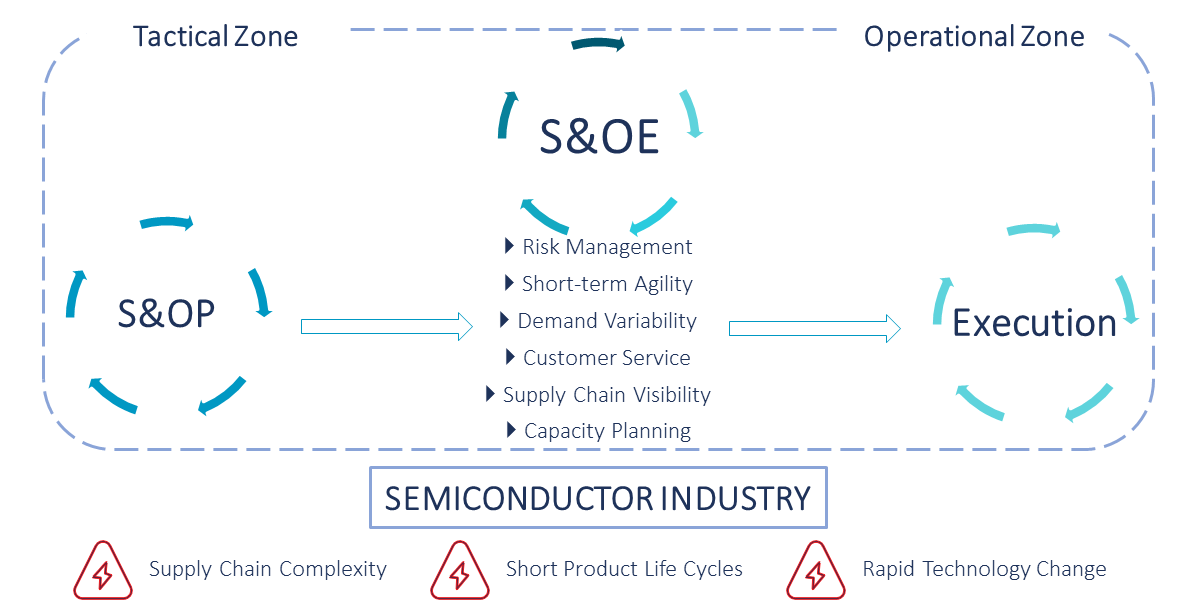

Sales and Operations Planning (S&OP) is a high-level strategic planning process that helps semiconductor companies balance demand and supply for their product portfolios focusing on 12-18 months. S&OP brings together cross-functional teams, such as sales, marketing, finance, and production, to develop a unified plan based on demand forecasts and operational capabilities.

Sales and Operations Execution (S&OE) on the other hand focuses on the short-term horizon, typically covering the next few weeks to months. S&OE plays a crucial role in the highly dynamic semiconductor industry, which is characterized by rapid technological advancements, short product lifecycles, and intense competition by bridging the gap between high-level strategic planning and day-to-day operations.

Aspects of S&OP in the Semiconductor Industry

S&OP is mostly monthly or quarterly planning involving the following aspects:

- Long-Term Planning: S&OP focuses primarily on long-term planning, typically covering a horizon of 12-18 months. It helps align the overall business strategy with the production and supply chain plans.

- Demand and Supply Balancing: S&OP aims to balance demand and supply over the long term. In the semiconductor industry, this means ensuring that production capacity matches anticipated market demand for various semiconductor products.

- Resource Allocation: S&OP helps allocate resources such as manufacturing capacity, materials, and labor effectively. It enables companies to make strategic decisions about investments in new fabrication facilities, technology upgrades, long-term capacity planning, and plans for outsourcing if necessary.

The Importance of S&OE in the Semiconductor Industry

In contrast to S&OP, S&OE is a weekly planning process, which bridges the gap between S&OP and execution by providing solutions to the problems occurring in the short term.

- Short-Term Agility: S&OE is focused on the short term, usually covering a horizon of a few weeks to a few months. It deals with the day-to-day and week-to-week challenges in manufacturing and supply chain operations.

- Supply Chain Complexity: Semiconductor manufacturing involves complex global supply chain networks with multiple suppliers and partners. Managing these supply chains efficiently is crucial for maintaining product quality and meeting customer delivery commitments. S&OE provides visibility into the supply chain and helps identify potential bottlenecks or disruptions.

- Demand Variability: In the semiconductor industry, demand can be highly volatile and subject to sudden changes. S&OE is crucial for adjusting production schedules and inventory levels in response to changes in customer orders, supply disruptions, or other unforeseen events.

- Customer Service: Semiconductor companies need to meet customer commitments and maintain high service levels, especially when serving industries that heavily rely on semiconductor components like consumer electronics and automotive. S&OE helps ensure timely delivery and responsiveness to customer demands.

- Short Product Lifecycles: Semiconductors often have short product lifecycles due to rapid technological advancements. S&OE enables companies to respond quickly to market shifts and adjust their production plans accordingly, ensuring that they produce the right products in the right quantities at the right time.

- Inventory Management: Managing inventory levels effectively is critical in the semiconductor industry due to the high cost and rapid technological obsolescence of components. helps balance inventory levels to meet customer orders while avoiding overstock or shortages.

- Capacity Planning: Semiconductor fabrication facilities (fabs) have limited capacity, and the production process is highly specialized and expensive. S&OE helps optimize fab utilization by balancing production across different product lines, prioritizing high-value products, and minimizing downtime.

- Risk Management: Semiconductor companies face various risks, including supply chain disruptions, component shortages, equipment breakdown, and geopolitical issues. S&OE allows companies to proactively identify and mitigate these risks through developing contingency plans by reallocating resources, adjusting production schedules, or sourcing alternative components.

To Summarize:

Sales and Operations Execution (S&OE) is indispensable for the semiconductor industry due to its ability to provide real-time visibility, agility, and decision-making capabilities necessary to thrive in a highly dynamic and competitive market. It enables semiconductor companies to meet customer demand, optimize production, manage supply chains efficiently, and control costs while ensuring customer satisfaction.