Lean management was strongly influenced by Toyota: Their production principle serves as a model for production that permanently eliminates waste. Our study “Lean meets Digital” shows that lean is still a current and relevant topic for manufacturing companies today. Still, despite its success, the implementation of lean philosophy meets stumbling blocks since it aims at long-term transformations. Many companies rarely experience benefit from further investments above a maturity level 3 in the Lean model, as shown in my previous blog. From an average maturity level of 3.5, measures bring fewer improvements. From here on, it needs digital enablers to improve business performance significantly.

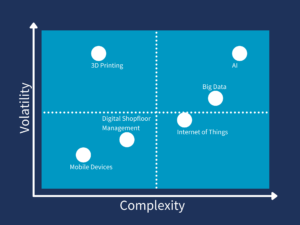

Lean Digital Matrix

The Lean Digital Matrix provides answers as to which technology and approaches can be helpful. It spans the two dimensions of complexity and volatility:

Volatility indicates how often there are changes in the environment.

Complexity describes how well the introduction or work with new technologies and digital enablers can be controlled. This is often reflected in the complexity of the connection or interfaces to adjacent or external systems, for example, to collect and evaluate data from suppliers and partners.

In answer to the question of which technologies bring savings and thus a higher level of lean maturity, the matrix provides information on two levels:

- Performance view: The matrix shows which digital enablers can bring the next leap in performance improvements when traditional lean methods, such as 5S and flow principles for processes on the store floor, have already been implemented.

- Benefit/investment view: The matrix also provides guidance on how much effort is required to introduce a digital enabler, and what investment is needed to manage complexity and volatility in the environment of a specific use case. The higher both are, the higher the benefits can be – with an increased amount of effort, which has to be accepted anyway from a certain Lean maturity level on. This needs to be evaluated in concrete terms.

I will show how the Lean Digital Matrix provides guidance with several examples:

AI as an enabler for highly volatile and highly complex use cases

In a highly volatile and complex environment, complex algorithms are needed at a certain point to quickly detect changes based on a great deal of data. This makes it possible to derive suggestions for action, such as ramping up or curbing the production of certain seasonal goods.

For example, the business of beverages bottling companies is affected strongly by the weather. People drink significantly more in warmer temperatures and during longer periods of hot weather. Hence the consumption of soft drinks is significantly higher in warm summers than in other seasons or during cooler summers. Unlike in Mediterranean countries, these hot spells cannot be planned in Germany. For beverages bottling companies, it makes sense to increase production beyond a certain base production level according to weather forecasts – and not simply 50 percent more because it is summer. This requires medium-term weather forecasts as well as sales figures from previous years in relation to historical weather data.

Performance view

This use case is sufficiently volatile – as weather is a non-influenceable component; at the same time, it is sufficiently complex as production lines need to be retooled at relatively short notice.

Soft drinks have a rudimentary shelf life. Still, with overproduction in summer, there will be too many goods in storage for the rest of the year, causing storage costs and administrative expenses. In the case of non-durable goods, the investment pays off even faster: For example, in early 2021 many brewers had to destroy vast quantities of beer was not ordered by the restaurant industry during the COVID-19 lockdowns (Link to German article). Many breweries have, in the meantime, cut back production (Link to German article). In an ideal world, the following applies: The more perishable the food is, the more quickly production processes must be capable of being changed over – from the supply chain to the shop floor.

Benefit/investment view

The AI example illustrates the second level of the Lean Digital Matrix: The more complex and volatile the use case, the higher the benefits and investment.

In order to support business processes in detail with AI methods, a high investment is required first of all for the introduction of the technologies, and then implementation, and on an ongoing basis. This is because the available technologies do not yet provide end-to-end support “out-of-the-box”, and powerful implementations for individual tasks must first be configured into a functioning solutions first. This knowledge is still expert knowledge to a large extent, and what’s more, each solution is specifically adapted to the use case and the available data – which in turn increases the effort involved.

A second effort-driver: Machine learning and AI rely on Big Data, a field that is already quite well established, but not yet a commodity. Collecting data is something that can be implemented relatively quickly, assuming of course that data protection laws and the like can be complied with. Storing and structuring these data (or not), in such a way that they can be evaluated with algorithms, also requires the assistance of experts.

Capabilities for more than one use case

If the conversion succeeds with the digital enablers, the probability of incorrect production is reduced significantly. In addition to this, the AI capabilities that have been established will be used for other use cases, for example, to realize IoT use cases with data from the production lines – from machine control all the way up to predictive maintenance.

3D printing for use cases with high volatility and low complexity

In medical technology we see cases, in which exactly one part is produced individually for each patient, such as a prosthesis or part of a joint. 3D printers are being used here increasingly for automated production, which significantly reduces the cost per part.

In the performance view, the use case environment shows itself to be relatively volatile, since each part is produced individually. However, the complexity in the environment tends to remain low: The 3D printer is installed once, and the risks involved are manageable. As the technology is comparatively mature, there will be product upgrades/updates only at reasonable intervals; and the complexity for integrating the 3D printer into the company network is also manageable.

The benefit/investment view reads favorably as well: Acquisition and operation can be managed in terms of time and cost. However, the effort for the production of the individual prosthesis parts remains in the actual manufacturing process, which requires CT scans, a computer-assisted process and a plastic model for each individual implant part. The 3D printing eliminates the need for the manual production of the part – with lower personnel costs. Combining the digital enabler of 3D printing with augmented reality (AR) opens up further potential, as this German article at Devicemed.de shows.

However, this use case also illustrates that, in addition to the traditional levers of process, organization, and technology, other influencing factors take on special significance in the work using the Lean Digital Matrix: For example, a hospital that uses a 3D printer itself becomes a manufacturer, including topics as product liability, etc. What’s more, the EU Medical Devices Regulation (MDR) also plays a special role. These factors must be taken into account in the business case.

Mobile devices for performance gains in use cases with low volatility and complexity

The two use cases shown so far provide answers for high volatility and, in the first case, high complexity. It is usually worth the try to work through use cases with low complexity and volatility first. In simpler manufacturing use cases, mobile devices can provide performance gains, e.g., when data is viewed directly on site, when labels are scanned, or quality checks are supported by mobile scanners.

In the performance view, mobile devices pay off quickly. They extend the traditional lean horizon, but involve lower complexity and lower volatility when it comes to implementation and operation: Established solutions are available for managing the devices, and even if the development process for them is relatively fast, no major leaps in innovation are to be expected in the short term (volatility). The risks to be expected during implementation and operation are manageable and their probability of occurrence is lower than for an IoT project, for example.

The benefit/investment view is also favorable: Various devices are already available for use in production lines or in the warehouses. The costs for implementation and operation can be calculated easily as one-time purchases, license costs and maintenance as well as training expenses.

Start with low complexity and volatility

The last examples show: It makes sense to digitally support the use cases with low volatility and complexity, before introducing the digital enablers with higher costs and effort. Anything else would mean blowing things out of proportion: Ultimately, AI technologies for manufacturing are based on other digital enablers, such as digital shop floor management and IoT scenarios, in addition to Big Data. In the end, more advanced use cases as predictive maintenance can only be realized with this data. More on this in an upcoming blog article.