The corona pandemic turns supply chain planning into what seems like a mission impossible. Supply chain leaders and demand planners need to find quick answers to complex challenges that most of them have never had to deal with before. In a short series of blog posts, we want to provide guidance on how to master demand planning successfully even in these difficult times.

The exploding VUCA world

For supply chain planners the increasingly difficult balancing of demand and supply in the VUCA world (VUCA = acronym for variability, uncertainty, complexity, ambiguity) is becoming a hard-to-achieve goal these days. There is no blueprint available on how to deal best with the challenges they are facing:

- In most areas demand is plummeting due to government regulations and corresponding store closures, consumer uncertainty and production stops.

- In other areas (e.g. medical accessories) demand and prices are exploding.

- Planners are overloaded with firefighting activities while facing availability constraints due to illness, remote work or missing childcare.

The three key challenges of demand planners

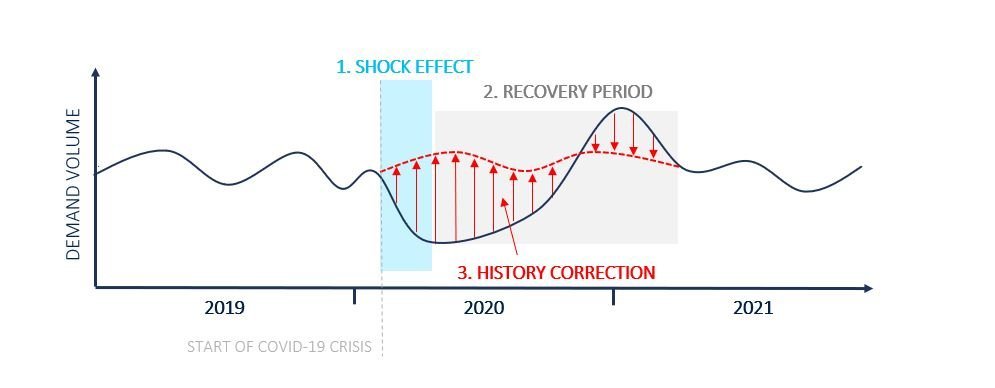

All supply chain planning starts with a good projection of the upcoming demand. So as a responsible demand planner you are now faced to come up with your best guesses on three different aspects:

- Immediate reaction to adjust forecasts in the short-term by estimating the current demand drop/uplift by product category and country/region (shock effect)

- Providing an outlook for the next weeks and months estimating the recovery period based on different pandemic curves

- Keep track of the corona sales effect to allow for later history correction

So now the tricky question is, how to respond to these challenges? We recommend to separate your activities into three different categories:

So now the tricky question is, how to respond to these challenges? We recommend to separate your activities into three different categories:

- What can you do immediately?

- What should you start doing?

- What should you prepare for in the mid-term?

Category 1: Do immediately!

The most efficient way to deal with a shock like the corona pandemic is to define a flexible adjustment approach which can be easily reviewed and corrected when new information is available. Instead of manually adjusting product-level forecasts or stopping statistical forecasting, the following procedure is recommended:

- Continue calculating a baseline forecast using historic pre-corona data. This can be achieved by either adjusting the historic horizon of your forecast models. An automatic outlier correction process might help you in the first month but could provide wrong results afterwards unless you define some more sophisticated correction models.

- Define impact curves on aggregated level, e.g. product category and country. Make sure to make this a joint activity in collaboration with your demand planner peers and as well as colleagues from sales and marketing.

- Document assumptions and the current situation (e.g. changing governmental regulations). This will allow you to easier review and finetune the curves with changing conditions and to learn from countries farther ahead in the cycle.

- Maintain the curves as percentage adjustment to the baseline forecast or as positive/negative events depending on your demand planning data model

Category 2: Start doing!

- Seek support from your forecast analyst to support you with insights from available external data sources. There is a multitude of data, and numerous researchers from across the globe are working to retrieve insights from it create data visualization and prediction models. Most of them are published as open-source packages to include in your personalized R or Python project. If you do not have a forecast analyst role with the right capabilities implemented in your demand planning department, it is worth looking for such an expert e.g. in your sales or marketing department or seeking external tool-based support. A good example for an external tool support is the COVID-19 Impact Analyzer for Supply Chain Management provided by CAMELOT Consulting Group.

- In order to have continuous support from an automated baseline forecast, you need to define a way to correct the historic data going forward. The good thing is, you can re-use your previous percentage forecast adjustments or events, review the quality of this and adjust your sales history accordingly.

- Define alternative scenarios in case there is unclarity and high risk, e.g. due to pending regulations or different views on the recovery cycle length. This will allow to build a robust supply chain plan going forward and define the best time for e.g. plant re-opening decisions.

Category 3: What you should prepare for!

- Make sure to document your decisions and assumptions linked to them. Only this will allow you to learn from the experiences and improve your future decision making.

- Build a resilient supply chain by including risk and variability in your planning.

- This starts with an efficient segmentation of potential variation. You should be able to easily distinguish fluctuation, disturbance and level shifts from butterfly or meteor impacts. Each of them requires a different reaction and different methods and tools. Supply chain resilience is the key word here, see this article for some more details.

- Your processes should be ready for that, e.g. via exceptional process and communication rules. Also, you need the methods and tools on hand. Think about introducing: Probabilistic forecasts, scenario planning, driver-based/assumption-based planning, external data integration etc.

Structuring your COVID-19 actions in this way should help you master what seems like a mission impossible: demand planning in times of unprecedented shock. In our upcoming article, we will explain how COVID-19 impact analyzer tools can help demand planners navigate through the crisis. Stay tuned!