In an increasingly volatile and uncertain external environment, companies need to fundamentally re-think their value chain model, and move to resilient operations, anticipative planning, and adaptive value chain design.

Watching the daily news, we all sense the increasing volatility and uncertainty in today’s societies and business world. Many call it hyper VUCA (Volatility, Uncertainty, Complexity, Ambiguity), others see the world becoming more “hot, flat, and crowded”. We think these claims have never been more true than today, as we can see in an increasing number and degree of disruptions like political quarrels, trade conflicts, and environmental incidents. All this goes along with an increasing polarization of views and often the loss of a clear consensus on future business developments. Take for example the future of globalization: Will globalization thrive more than ever before fueled by the free flow of information and goods, and the rise of a new middle class in emerging economies? Or are we headed towards a post-global world, with more and more trade barriers, restricted flow of information, and diverging technological standards? Similarly, you will see highly polarized views on the outcome of major events like Brexit, the societal impact of digitalization, business impact of climate change, and so on.

Weathering the storm

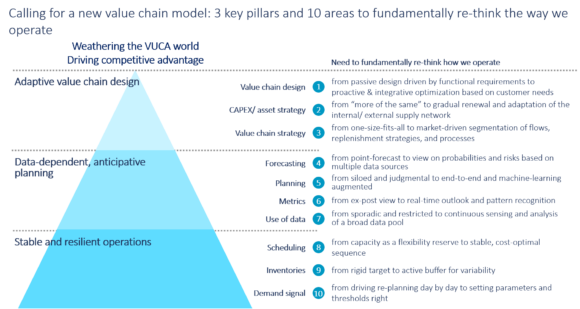

How should businesses think about their value chains in such a radically changing and highly uncertain external environment? Based on our own research and discussions with our clients, we at CAMELOT think companies need to transform towards a new value chain model based on three critical pillars:

Stable and resilient operations

Minimal internal variability, noise, and firefighting—these are critical prerequisites for handling truly disruptive external events, and freeing up critical management capacities for building strategic flexibility. Here, companies will need to re-think how they use demand signals (from daily trigger for re-planning to setting ranges and parameters right), inventories (use as an active variability buffer), and scheduling (move to a cost-optimal, stable sequence). In other words, companies still have a lot of opportunity to make their machine room much more smooth, stable, and efficient through a new planning and scheduling approach. Only if they run as stable as possible when the sea is calm will they have the required resilience when the storm gets rough.

Data-dependent, anticipative planning, and optimization

The shortcomings of today’s value chain planning are limited use of data, ex-post orientation, partial optimization, and deterministic view, which altogether lead to massive re-adjustments and a reactive management mode. Companies need to turn towards a more data-dependent and anticipative approach, which is grounded in systematic data-screening and pattern recognition, e.g. through correlations, divergences, and rate of change. Planning strategies need to actively anticipate key alternative outcomes (based on probabilities) and optimize the end-to-end value chain with the help of machine learning and data & analytics.

Adaptive value chain design

In the new environment, companies will no longer be able to afford rigid, inflexible value chain designs and asset strategies which effectively lock in >80% of total cost and structural capabilities for many years. Similarly, lack of integrative design between commercial, development, and operations costs many companies millions in sunk cost. An adaptive value chain design is needed which optimizes the value chain early in a cross-functional approach (design for growth, profitability, and sustainability) and changes the millions spend each year on CAPEX into a driver of continuous renewal, innovation, and strategic flexibility as opposed to cementing “more of the same” and inflexible operating model.

The figure below shows the 10 key elements where companies need to fundamentally re-think the way they operate their value chains.

A new approach

We know from experience that achieving the above is a major challenge and long journey for any company. Re-thinking the value chain of the future is not one-dimensional, but deeply impacts processes and learned ways of working, roles, capabilities, organizational culture, and structures, as well as enabling technologies. Addressing any of these factors alone will not make a change, thus we are calling for a new integrated value chain management approach.

However, we know equally well that today’s value chains with its inflexible structures, reactive planning, and internal noise and firefighting are not set up to compete in a more and more volatile and disruptive environment. Thus, starting the journey is not a question of if, but of how.

But the good news is, there is payback along the way. In one of our recent projects, a global consumer goods manufacturer has taken the step towards a stable manufacturing model and has improved its supply chain planning based on the Demand-Driven principle. The results were not only a significant increase in customer service, but also a strong reduction in inventories and operating cost through efficiency gains in a more stable value chain.

How is your company reacting to the increasing volatility and complexity of the environment? Which steps of the journey have you taken already, which are you struggling with? Please let us know your feedback and thoughts ….

We will continue this blog series with a more detailed blueprint of the new value chain model in the following articles.