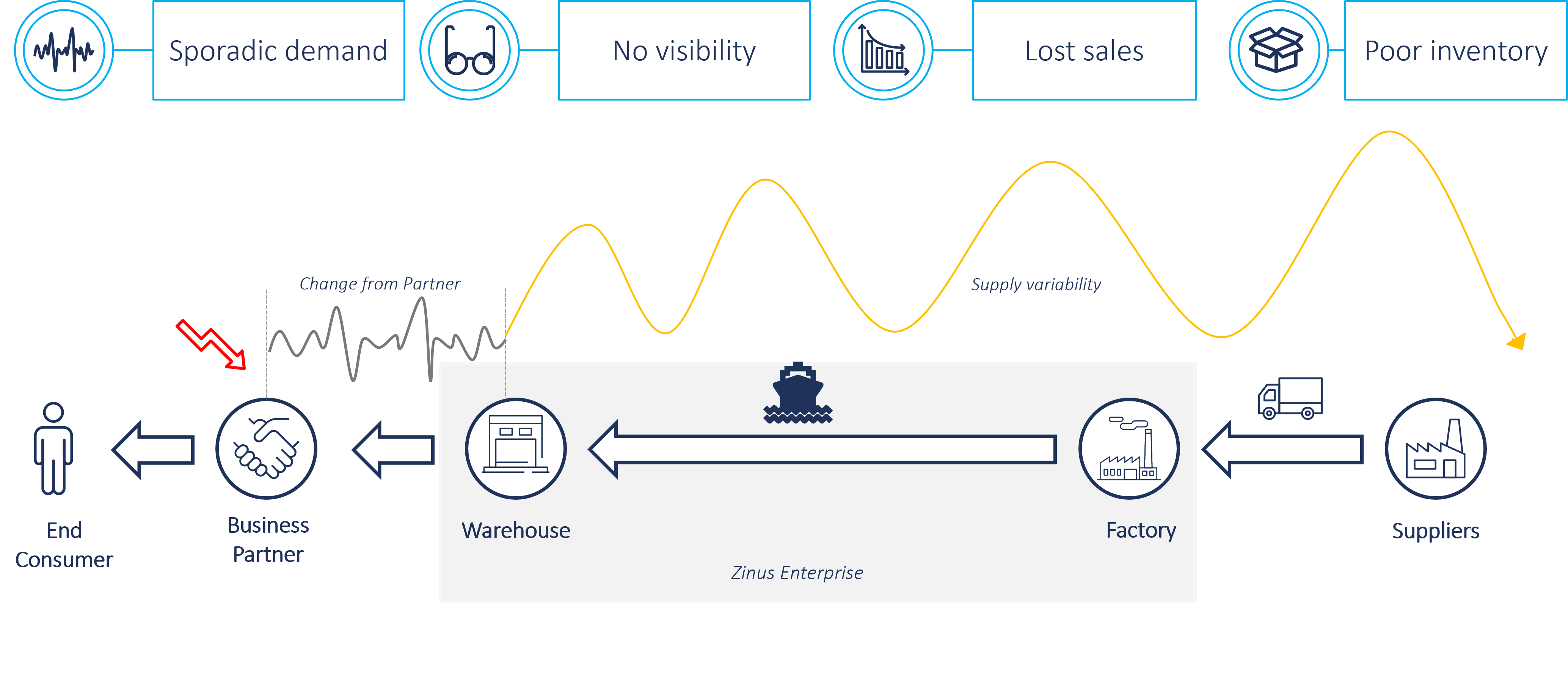

Have you ever imagined why a machine learning algorithm seems to be the only answer to better forecasting accuracy specially in cases of sporadic demand? And if yes, is only better forecasting the answer to your value chain problems?

To better understand the underlying challenge of today’s world, let us take a look at an example in e-commerce business. With access to the Internet and online shopping becoming more and more part of our daily life, e-commerce business is flourishing. E-commerce is catering to a market segment which is B2C (business-to-customer) whereby the demand patterns in today’s e-commerce business can vary drastically from month to month, based on the end consumers’ buying patterns. This makes demand forecasting a tricky task. In cases of sporadic demand, a new approach called collaborative planning, forecasting and replenishment, or CPFR in short, delivers high forecasting accuracy. It also results in advanced collaboration across the value chain, optimized inventory management, and it raises the overall supply chain efficiency.

When we hear the word ‘sporadic demand’ we sometimes jump to machine learning algorithms such as ‘gradient boosting’. Even though a machine-learning-based approach delivers good results in other planning scenarios, the solution falls short when the data points at product level are in their single digits, often as low as three or four transactions per year. From our experience with cases like these, regardless of the aggregations we make for these products, forecast accuracy will not be close to acceptable market standards.

If we take a step back, another thought comes to mind: Is it really a forecasting problem that we want to solve? Or do we have a much bigger task at hand? Yes, we have, and this much bigger task is adding the concept of collaboration across the value chain to the equation. Let’s understand this problem better with a help of retail industry.

Demand Forecasting Leveraging Collaboration across the Value Chain

Some of the bigger players in the market such as Amazon and Walmart were able to find ways to forecast their priority segment-A products with a satisfactory level of accuracy. To be able to offer the products, they rely on their suppliers. They in turn must solve the problem of predicting the buying patterns of Amazon or Walmart – which, again, may be sporadic, depending on factors like:

- promotions for products

- the company’s sales strategy,

- market trends and end consumer feedback,

- the opportunity cost of any lost sales,

- target inventory levels to be maintained,

- inventory holding costs.

At first glance, this makes it almost impossible for the suppliers to predict the buying patterns of their B2B customers. This, in turn, impacts the working capital, customer service levels, lead times to deliver the orders and lost sales opportunities.

In this context, the proven concept of ‘collaborative planning, forecasting and replenishment’ (CPFR) helps to deliver better efficiency across the value chain.

CPFR focuses on a collaborative effort from all parties in the value chain and create on single efficient plan. The partners exchange demand data, so they can act on opportunities. The underlying CPFR process streamlines many value chain functions, lowers costs in inventory and logistics, and improves supply chain efficiency and inventory movement. By establishing a common process and defined metrics, CPFR aids retailers and suppliers in improving their processes and reaching their goals.

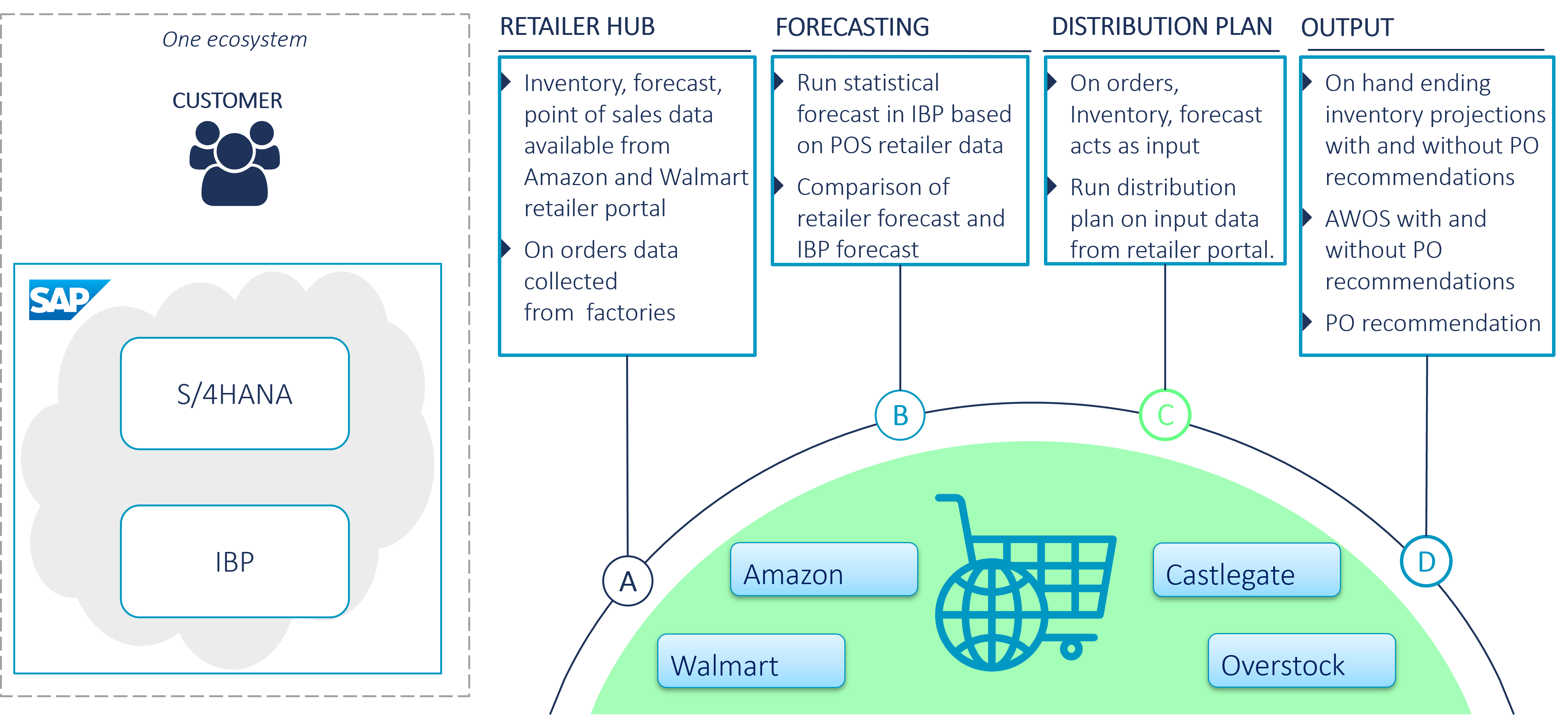

Implementing CPFR using SAP IBP

With only four steps, you can support the whole value chain ecosystem right from the supplier to their customers and including end consumers.

- Make information available across the value chain: Leverage information such as Point of Sales, inventory targets, current inventory levels across the value chain including B2B customers and make the information readily available on SAP IBP as a single platform to support informed and quick decisions.

- Create one business plan: The formulation and consensus-building of the business plan should occur right from the start. This guarantees that all stakeholders within the supply chain are aligned with a unified objective aimed at the prosperity of the enterprises.

- Close collaboration on exceptions: A single platform powered by SAP IBP acts as a single source of truth to identify and manage exceptions all throughout the value chain. Any discounts offered to clear the stocks and any promotions are visible for the manufacturer but also for the retailer.

- Generate the orders: After all the agreements, generate the orders which is a win-win situation for both the manufacturer and retailer.

Some of the key benefits that CPFR has brought to our customers are:

- Strategy and planning are improved – strategy and planning are well aligned across the partners in the value chain. This improves overall transparency while working towards a common goal.

- Less dependency on traditional ways of forecasting – though forecasting is still a part of the CPFR process, it is only one of the inputs, and not all decisions are dependent on it.

- Better preparedness for any supply chain disruptions – any disruption in the value chain is captured early, making it easier to adapt and act on it better than before for all value chain partners.

- Improved E2E profitability – enhanced demand and supply management establishes the profit objectives, encompassing the company’s order planning, order forecasting, and realized sales activities.

In our experience, CPFR has brought a lot of benefits to our retail customers, especially as decisions throughout the value chain are based on facts, the partners profit from higher transparency while also making the value chain more resilient to risk.

Building Value Chain Ecosystem with CPFR

CPFR gathers all stakeholders of the value chain in a single ecosystem, including the customer’s customer. This goes a long way towards fact-based decision making. As can be expected, there is no ‘one fits all’ strategy’ for CPFR implementation. It builds on iterative processes that are process-driven, which means that it needs to adjust to the working practices in the partner companies. There needs to be a change in internal processes as well to adapt to the new normal on implementing CPFR.

Are you interested in finding out if CPFR is a fitting approach for your business? Do not hesitate to reach out.