Transport management is an essential part of any organization’s supply chain and it can be one of the most challenging and expensive aspects. As the world becomes increasingly connected, transportation risks continue to increase and companies are seeking ways to optimize and reduce their transportation costs. This is where risk management comes into play.

Risk management is a set of processes, methods and tools that organizations use to identify, assess, and mitigate risks that could impact their operations. In the context of transportation, risk management involves identifying potential risks in transportation, including delays, disruptions, and security issues. By identifying these risks early, organizations can take proactive measures to prevent or mitigate them, ultimately saving time and money.

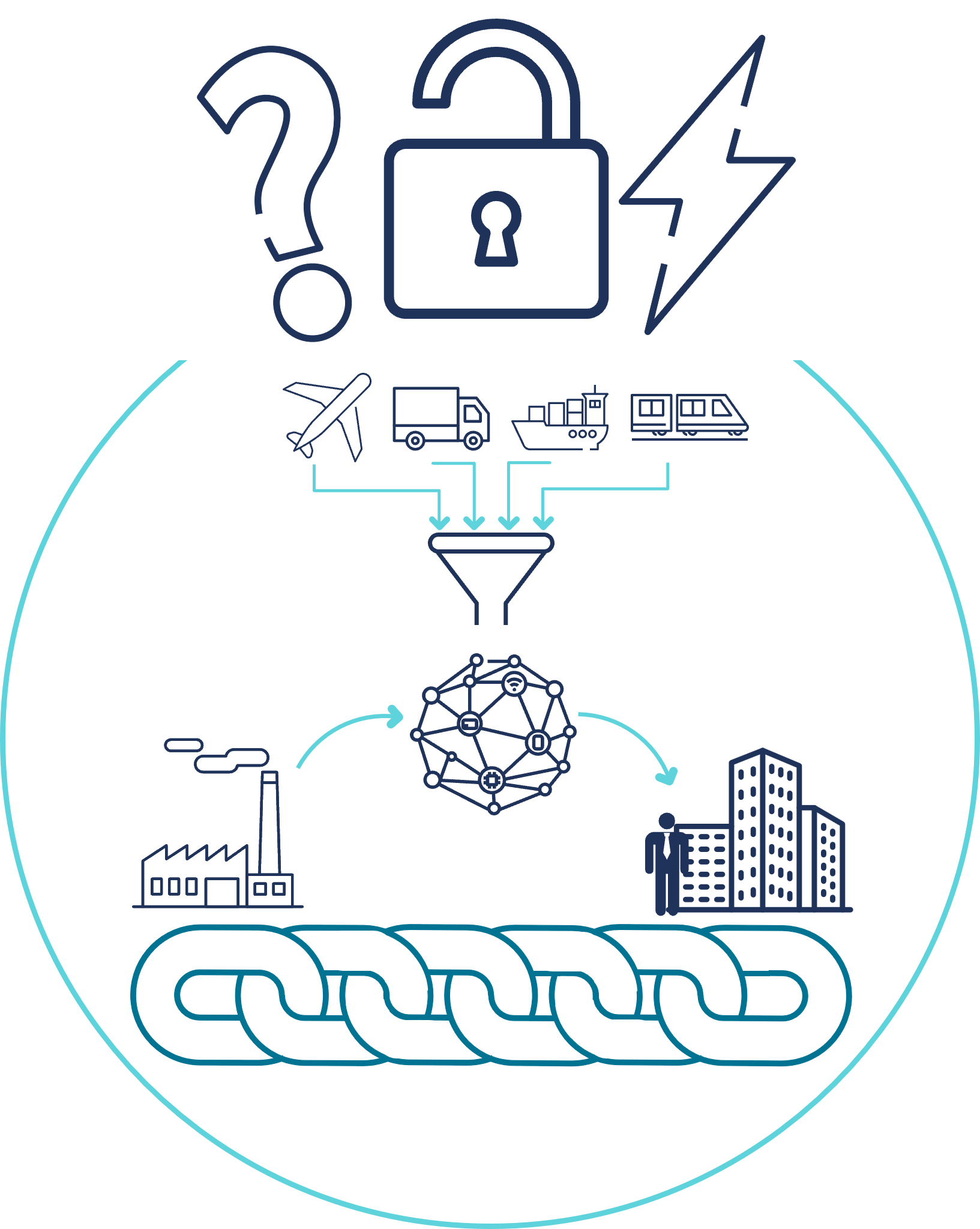

Let’s have a look at possible risks that can negatively impact the supply chain:

- Operational risks in logistics encompass a range of challenges that directly impact an organization’s ability to meet customer demands on a day-to-day basis. These risks require careful management to ensure operational efficiency. Examples of operational risks in logistics include transportation disruptions, equipment failures, supply chain disruptions and human resource risks.

- Transportation disruptions pose a significant risk, potentially leading to delays and disruptions in the delivery of goods. Factors such as traffic congestion, road closures, or flight cancellations can hinder the smooth flow of logistics operations. Proactive measures like monitoring traffic conditions and implementing contingency plans are essential to mitigate these risks and maintain efficient transportation processes.

- Equipment failures present another risk that can impede logistics operations. Breakdowns or maintenance issues with trucks, ships, or planes can result in delays, increased costs, and compromised customer satisfaction. Regular equipment maintenance, effective fleet management, and having backup options in place are crucial to minimize the impact of equipment failures and ensure uninterrupted operations.

- Supply chain disruptions can have severe consequences on logistics efficiency. Delays or quality issues with suppliers or subcontractors can ripple through the entire supply chain, leading to bottlenecks and compromised timelines. Building strong relationships with reliable suppliers, diversifying sourcing options, and implementing robust quality control measures are essential to mitigate supply chain risks and maintain operational effectiveness.

- Human resource risks can also significantly affect logistics operations. Labor shortages, strikes, or absenteeism can disrupt schedules, create delays, and strain the workforce. Effective workforce management, contingency planning, and fostering a positive work environment are vital to address human resource risks and ensuring smooth logistics operations.

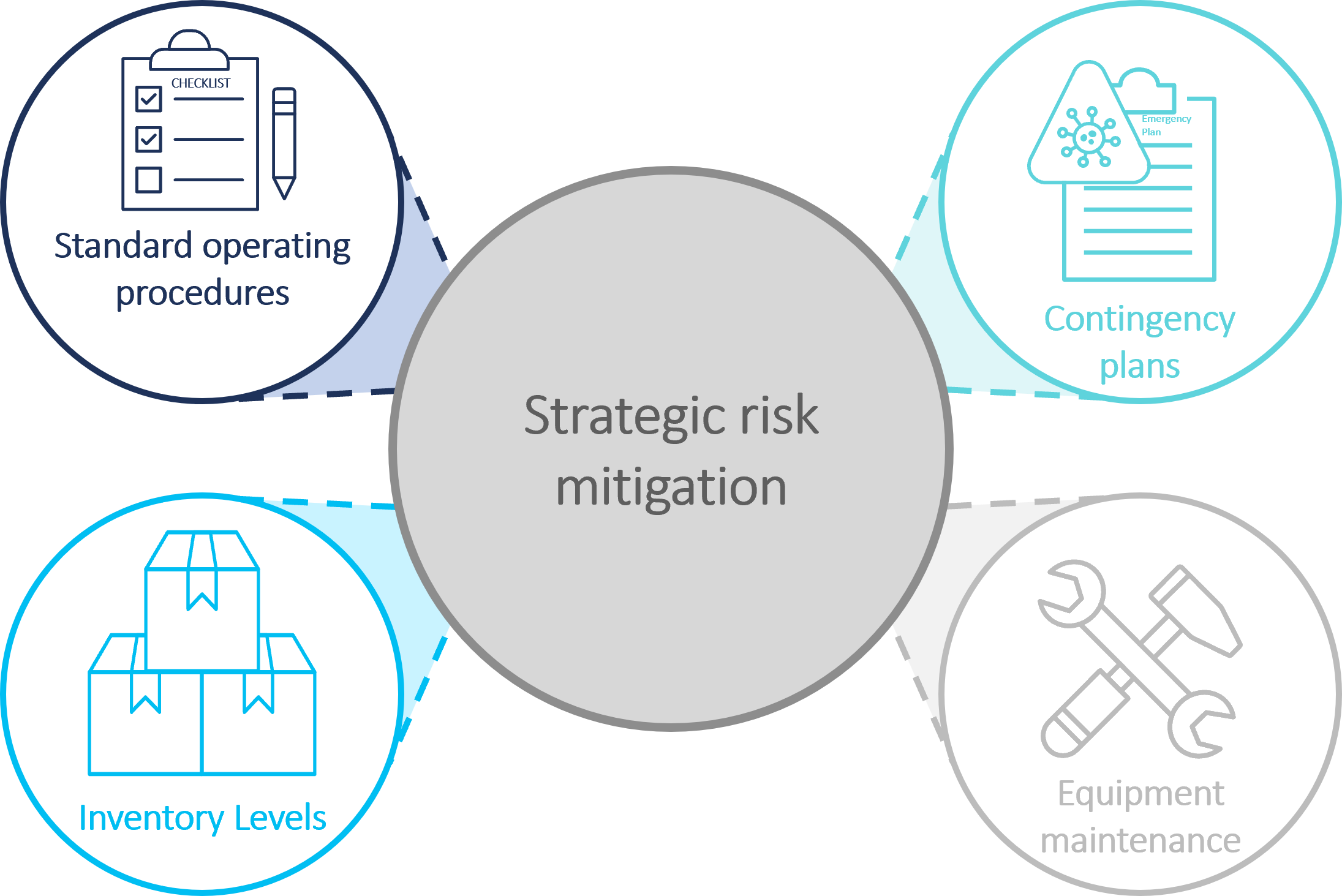

Strategic Risk Mitigation Ensures Efficiency and Resilience

After a company assesses the risks, risk mitigation strategies are developed and implemented. Mitigation strategies may include implementing standard operating procedures to ensure safe and efficient operations, increasing inventory levels to buffer against disruptions, improving equipment maintenance and repair processes, and developing contingency plans to address disruptions. To effectively manage risks at different levels, logistics professionals must have a detailed understanding of the logistics processes and activities that they are responsible for. This requires regular monitoring of logistics activities, analyzing performance metrics to identify potential areas of improvement and collaborating with other stakeholders, transportation providers, and other partners to develop contingency plans and ensure that all parties are prepared to respond to potential disruptions.

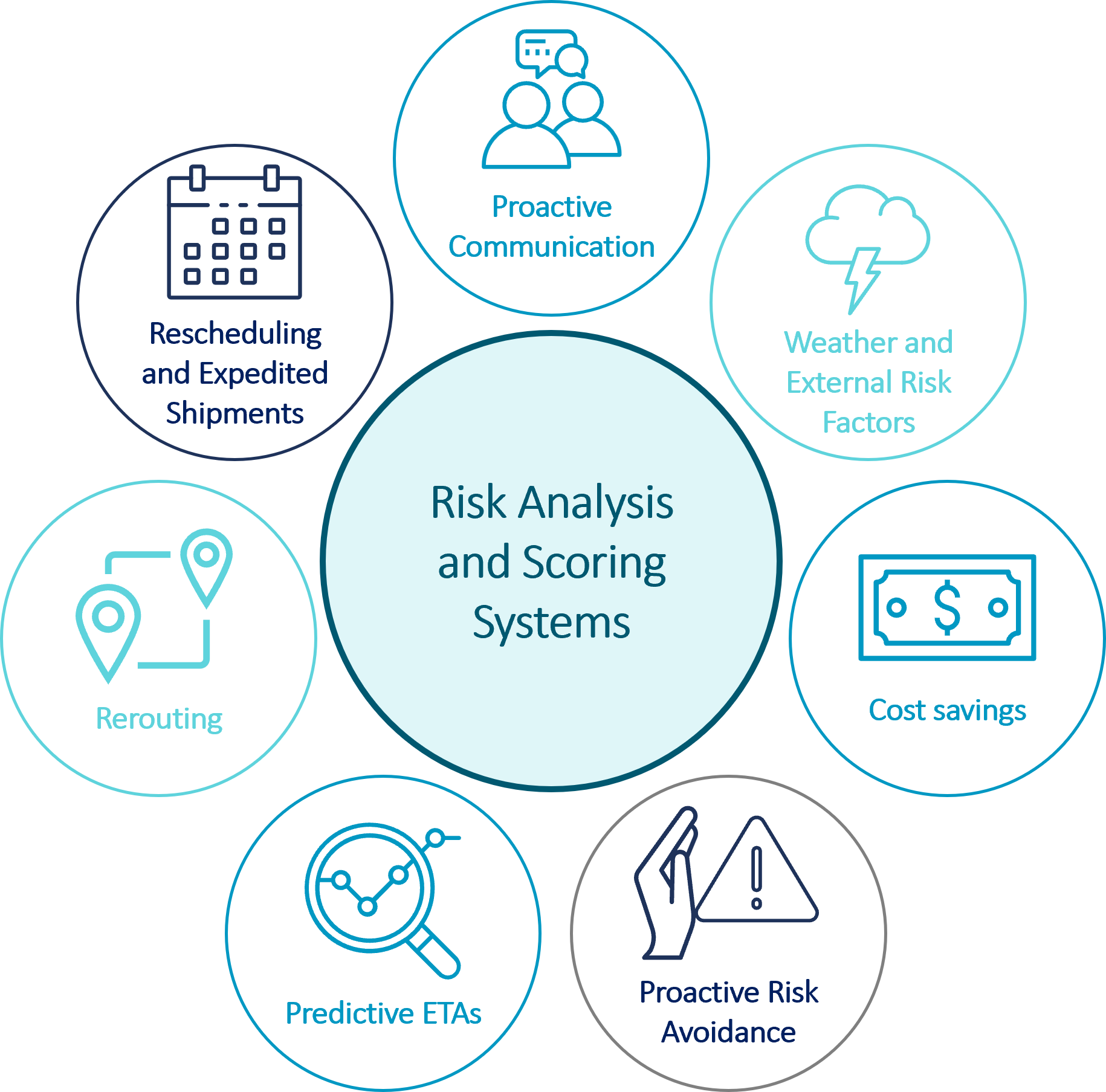

Risk Analysis and Scoring Systems Support Strategic Risk Mitigation

Risk insights in logistics provide valuable benefits for supply chain management, operational logistics processes and logistics planning. Logistics managers can make informed decisions and outpace the competition by incorporating risk analysis and scoring systems provided by companies such as Everstream Analytics. Some of the key advantages of risk insights include:

- Proactive Communication: Supply chain managers can communicate potential delays or disruptions to relevant stakeholders in advance, enabling proactive communication and minimizing the impact on customers and partners.

- Rescheduling and Expedited Shipments: Logistics planners can reschedule appointments and adjust shipment timelines to avoid or minimize potential delays. They can also choose to expedite shipments partially or fully to ensure on-time delivery.

- Rerouting: If a specific route or location poses a high risk of delay or disruption, logistics managers can reroute shipments to alternative paths or destinations, reducing the impact of potential risks.

- Weather and External Risk Factors: Logistics planners can leverage meteorological data and insights on external risk factors like weather events, labor actions, port closures, and more. This information helps identify shipments with a high probability of delay, allowing proactive decision-making and risk mitigation.

- Predictive ETAs: Advanced analytics can provide a predictive estimated time of arrival (ETAs) by considering various factors such as carrier performance, historical data, and industry trends. This enables logistics planners to choose carriers strategically, understand tendencies of lateness for recurring shipments, and identify shipments with a high likelihood of delay based on external risk factors.

- Cost Savings: Risk management in operational logistics can lead to cost savings by improving on-time delivery performance, reducing avoidable expedited freight costs, saving time spent on tracking shipments, and even decreasing CO2 emissions. It allows for better decision-making in strategic planning, optimization efforts, and streamlining processes.

- Proactive Risk Avoidance: By leveraging risk insights, organizations can proactively avoid risks rather than reacting to them. This shift in operations enables businesses to respond effectively to dynamic risks, save time and money, and convert their supply network into a competitive asset.

Increased Overall Supply Chain Performance and Customer Satisfaction through Risk Management

So, in addition to cost savings and risk reduction, transportation risk management offers a range of other benefits to organizations. By taking a proactive approach to risk management, organizations can improve their overall supply chain performance, including on-time delivery, customer satisfaction, and operational efficiency. This can result in improved customer retention, increased revenue, and a competitive advantage in the marketplace.

At CAMELOT, we specialize in optimizing supply chain operations. One aspect of our wide range of expertise is to incorporate risk management. Together with our partners, we provide easily accessible and understandable risk insights, integrate with existing platforms and transportation management systems, and offer user-friendly interfaces for effective oversight and management. This approach helps our clients save costs, reduce risks, and improve their overall supply chain performance.

Visit our Transport Management website for more information or contact us to learn more about how we can help you optimize your transportation management process and reduce your overall transportation risks.