How can we transform supply chain execution by improving the integration of SAP transportation and warehouse processes? How can we address common pain points of transportation and warehouse planners such as inefficient use of resources, limited process visibility, low process control, etc. Let’s explore potential solutions to these pertinent challenges based on SAP applications.

SAP EWM (Extended Warehouse Management) and SAP TM (Transportation Management) are two integrated solutions offered by SAP that support industry 4.0 initiatives by providing advanced capabilities for supply chain execution improving processes such as warehouse picking, transportation planning, loading optimization.

There are different approaches in order to get rid of weak or error prone logistics and transportation processes: enhance visibility, focus on transparency and collaboration across the entire supply chain execution platform, reduce costs and create more value for their customers.

Five Approaches to Closer Integrate Transportation and Warehouse Processes

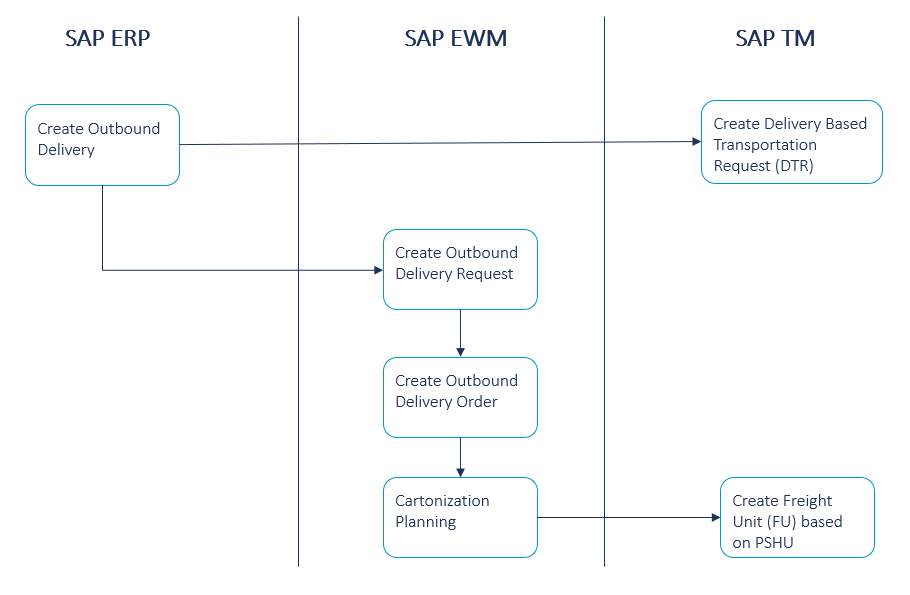

1. Cartonization Process

Business benefits come from integrated planning of future workload for all activity areas in supply chain execution from unloading, putaway, picking, packing and loading. One prerequisite of being able to plan is the knowledge of the expected workload in logistical quantities, like pallets or different handling units (HU’s). This can be done by using the SAP EWM cartonization process.

This process makes it possible to know the number of handling units in advance and their size by activity area based on the order, even several days before actual picking has started. Knowing this information in advance before the actual picking process has started itself, we can derive the amount of pickers we will know need in every shift per activity area which can significantly optimize our planning for the warehouse personnel and their utilization.

Because these planned shipping handling unit (PSHU’s) are sent to SAP TM as freight units (FU’s), the planner can now know the number and actual size of HU’s even several days before picking has started. Planners can then use this information for managing a better carrier and resource selection, which at the end results in improved loading space optimization and reduction of transportation costs. Transportation costs are cut because planner know now in advance based on the PSHU’s how much loading space is really needed and when. With this information they can now improve booking of trucks in advance with the possibility of cutting prices.

Key benefit of cartonization process:

- It might help to increase the efficiency and utilization of transportation resources

- By properly loading and packing goods, companies can lower the amount of trips needed to deliver their goods. This leads to lower fuel consumption and furthermore reduces wear and tear on vehicles. Additionally, by maximizing the loading space, businesses can also reduce the number of vehicles needed to transport goods, which might result in lower maintenance and insurance costs.

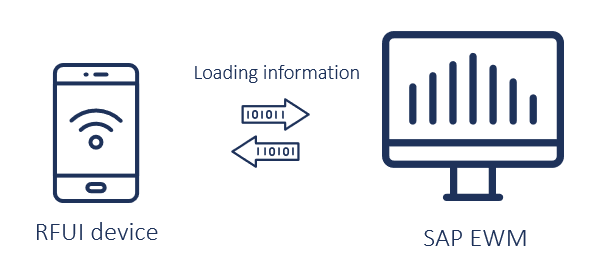

2. Integration of RFUI devices with warehouse and transportation process

RFUI devices can be directly connected to SAP TM transport execution. RFUI devices represent all devices that can use the SAP EWM RFUI app / transaction in order for them to get connected to the SAP EWM. One common use case for such devices in the context of loading is the so called ‘Execution Driven Planning’. Transportation only estimates required capacities instead of planning individual deliveries. After pick & pack, the HUs are directly loaded into containers or trailers. With RFID, the status is automatically updated and the HUs are linked to the transportation order (freight order). For instance, “Loading begin” status can be activated when we scan first HU with the RFUI device, and “Loading end” status will be set when we scan the last HU that needed to be loaded into a certain truck. Other than that, the “Loading instruction” can be transferred from SAP TM to SAP EWM so goods can be loaded based on unloading locations following the principle “First in, last out”.

Key benefits by Integration RFUI devices:

- Increased efficiency: Optimizing the loading process can help speed up the loading and unloading of products, reducing the amount of time required to move goods in and out of the warehouse.

- Reduced labor costs: An optimized loading process can help reduce the amount of manual labor required, which can lower labor costs.

- Improved transparency for planners, they can have real-time insights of loading process and they can use this information for better planning.

3. Transportation and warehouse monitoring capabilities

Withing the integration it is possible to have complete transparency and access to monitoring of the pick, pack, track, and settlement process in one place, as this will result in an improved overall visibility of your supply chain execution. Employees can search and view the complete history of a certain product or HU in the SAP EWM monitor or SAP TM’s transportation cockpit and can also make use of the track and trace functionality.

The transparency created therefore goes beyond systemic boundaries and is based on the current physical flow. To further push transparency within the supply chain processes a visibility assessment can be a perfect tool to discuss at which certain point, for which stakeholder needs which kind of transparency need to be provided, at what time and for pursuing which purpose and target.

The interaction of visibility data, its linkage and its integration into the logistic context is what provides the real added value to a customer.

Key benefits of transportation and warehouse monitoring capabilities

- Enhanced Data Tracking: With complete coverage of the process, you can easily track and monitor all aspects of the supply chain, including inventory levels, shipping times, and customer orders.

- Better Inventory Management: A comprehensive coverage of the process can help you better manage your inventory levels and avoid stockouts or overstocking.

- Improved transparency: Real time insights of transportation and warehousing processes.

- Complete overview: accurate and complete history of every customer order.

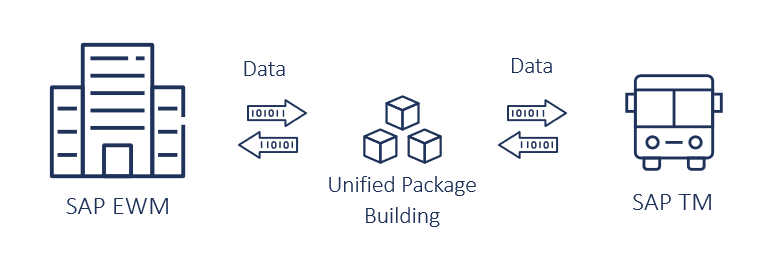

4. Unified package building

Unified package building can also be used in the integration scenario. Overall, SAP Unified Package Builder for SAP EWM and SAP TM are powerful options that can help users to create customized packages that meet their specific business needs. This feature simplifies the package-building process and allows businesses to quickly and easily configure their SAP EWM and SAP TM systems to optimize their logistics and transportation operations. This acts as a central component where packaging details and information can be maintained in one place for both systems.

Benefits of Unified Package Building:

- Optimization of transportation planning: By leveraging SAP Unified package building and HU building, businesses can optimize their transportation planning process by creating customized scenarios that consider various factors, such as transportation capacity, transit times, carrier requirements, and handling costs. This optimization can result in more efficient transportation planning and reduced costs.

- Enhanced packing execution and quality: Keeping information related to packaging centrally, the information obtained in this way is more transparent and the possibility of error is reduced significantly.

5. Advanced Shipping & Receiving (ASR) functionality

ASR is a new solution available for integrating and streamline logistics execution processes with main focus on transportation and warehouse applications. The ASR functionality of SAP S/4HANA provides features to model integrated transportation and warehouse processes, simplifies communication between SAP applications and improves visibility across the logistics execution processes. To gain more about the functionality please have a look to our blog article Integrated Logistics Execution Processes with SAP S/4HANA ‘Advanced Shipping & Receiving’ – CAMELOT Blog (camelot-group.com)

In conclusion, a closer integration of SAP EWM and SAP TM provides a comprehensive and streamlined supply chain management solution that can benefit businesses in various ways. With real-time visibility, better planning and execution, increased efficiency, enhanced customer service, and better compliance, businesses can optimize their operations and gain a competitive edge in the market.

SAP EWM and SAP TM integration does not only enhance the interaction and coordination between transportation and warehouse operations but also provides businesses with required tools and features to make data-driven decisions, reduce manual effort, and improve accuracy. Ultimately, integrating EWM and SAP TM is an investment in the long-term success of a business by optimizing supply chain operations, improving customer satisfaction, and reducing operational costs.

Our Camelot logistics team has a deep understanding and expertise gained through various projects focusing on an effective approach to optimize SAP software solutions to streamline our customers’ logistics execution processes.

If you want to know more about how to envision your future logistics and get inspired how to improve weak spots you need to work on, don’t hesitate to contact us.

We would like to thank Milan Nikolic for his valuable contribution to this article.