The Mantra of the 21st century: those who better manage their data drive their business to be more competitive in the future. Even though this is known by everyone, many businesses still do not operate at their highest capacity because of poor data management. Our experience with customers revealed how detrimental outdated data may be for the business. In this article, we provide the solution how one can solve these problems.

Is Your Business Ready to Meet the New Data Challenge?

The advancement of modern technologies has allowed us to collect an unprecedented amount of information and make data-driven decisions. In many organizations, data have become the lifeblood, but there is the flip side as well.

“Only from 2018 to 2025 the amount of data is expected to grow by 5 times, from 33 zetta-bytes in 2018 to a mind-boggling 175 ZB by 2025”.[1]

The data not only bring new opportunities, but it also carries costs and risks. More data require more technological capacity and human resources to store, engineer, clean, maintain, structure, and analyze. Digital transformation is the reality most businesses are already facing.

The supply chain is an inevitable part of this transformation. Basically, any event in every big manufacturing business, let it be a purchase of a new component or a payment to a client, runs in two parallel worlds: a real-world case and in a digital representation.

The more complex your business gets, the more the complexity shows in the supply chain management system. Take a moment and ask yourself the following questions: Do you need everything stored in your system? Is all information up to date? Do you have a dedicated team to take care of your data?

If your answers are primarily ‘no’, there is certainly room for an efficiency gain.

What Is the Impact of Having Outdated Supply Data in the System?

Let us start with a down-to-earth example. Why do people do a ‘spring-clean’ and get rid of things they don’t need anymore? Because it makes your apartment comfier, saves on the effort for cleaning and potentially frees up the space for purchase of new beloved things.

What a home is for comfort, a supply chain management system is for the functioning of a firm. It delivers everything the business side needs for day-to-day operations. And like a home, it needs to be taken care of in terms of data.

Despite that, it is very often the case that supply data are full of inactive not used materials, ranging from suppliers that you worked with years ago, to outdated components and production materials.

The lack of attention to supply data management has its consequences and here are some of them:

The outdated data in the system decreases the efficiency of business processes.

The outdated data are not trustworthy and may result in the wrong decisions with detrimental consequences for your business. Therefore, first you have to make sure that the data are correct, which takes a lot of time and resources.

The capital is blocked on excess inventories not in use.

The materials may virtually exist on your warehouses, but physically not be there because of outdated data. As the result, these virtual materials unnecessarily occupy your storage space, freezing your money and capital.

It takes additional effort and time for a new system implementation or data quality management activities.

The bigger the system gets, the more resources it requires to maintain. It is especially apparent when it comes to time- and resource-consuming processes like data quality management or an S/4 HANA implementation.

When Is Optimization of Supply Data Particularly Useful?

Coming back to our down-to-earth example, a ‘spring cleaning’, there is a best time and reason to implement a data optimization. Based on our experience in customer projects, we identified three major business cases when the optimization of supply data is useful:

- Moving to S/4HANA: data optimization helps to reduce the amount of data that needs to be migrated

- Reduction of goods on stock: data optimization drives down warehouse management cost

- Planning data quality management initiative: data optimization decreases the effort for data cleansing

How to Optimize Your Supply Data: Camelot Data Analyzer

If your business came to the point when it is the time to critically evaluate materials in your system and optimize them, there are two alternatives. You may decide to implement these activities in-house. However, if your business is limited in resources and your supply chain management is extremely complex, you might think of outsourcing.

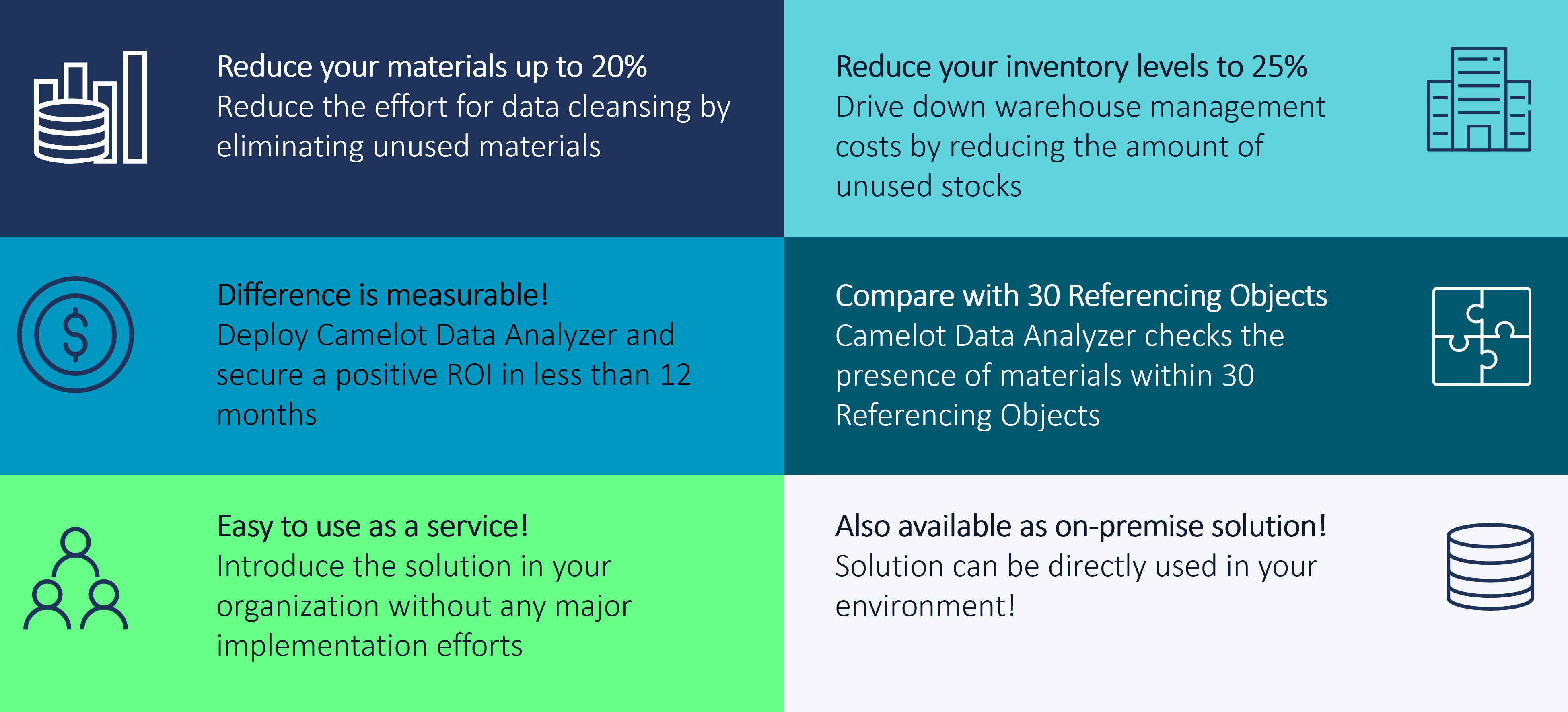

In case you choose outsourcing Camelot ITLab has the solution – The Camelot Data Analyzer. It performs the full cycle of material analyzing jobs by scanning the business transactions and their dependencies. In the end our clients get an easy definition of a way forward to achieve the desired results.

Give Data Purpose to Support Change

The world is fast-changing, and so should your business processes. Part of this change is smart supply chain management. Presence of outdated data decreases the efficiency of your business, slows down the system and blocks capital. Therefore, it is crucial to address this challenge, especially if you plan an S/4HANA implementation, a reduction of stock or further data quality management activities. Keeping track on your data saves financial resources and secures the positive returns for the future. Camelot Data Analyzer is easy to use tool to give your data a purpose.

[1] from 33 zetta-bytes in 2018 to a mind-boggling 175ZB by 2025. This massive 61% CAGR was put forward by IDC‘s latest “Data Age 2025” whitepaper. Unternehmensgeschichte | Seagate Deutschland