Scenario planning helps to reduce uncertainties in planning. The article provides insights in how to set up a scenario planning in S&OP without building too much complexity. This article is part of a blog series on S&OP/IBP. Learn here, why S&OP and IBP are still necessary and how to design S&OP processes.

We all prefer to make decisions under safe conditions. But in supply chains, this is hardly possible. Especially in today’s uncertain times, we are forced to make decisions under assumptions every day. Demand and supply uncertainties are hard to be predicted by orderly scenarios. We often see only one answer to uncertainty: a general increase in the safety stock that is supposed to cover both demand and supply variability. To meet the general call for a joint consideration of demand and supply scenarios, we recommend a pragmatic approach without letting the complexity grow immeasurably.

In our experience, many companies work with only one forecast case for S&OP for fear of too much complexity. Often double counting of competing products and non-consideration of new products happens, which might lead to operational problems such as wrong capacity allocation in the supply network and wrong fulfillment of market demands. With a pragmatic consideration of scenarios in the planning process, various benefits can be achieved. Cross-functional transparency on demand, less scrap risk, prevention of backorders, and a decrease in lost sales are only a few to mention. How to achieve these benefits? The following S&OP scenario circle provides guidance on the phases.

1. Develop Demand Scenarios

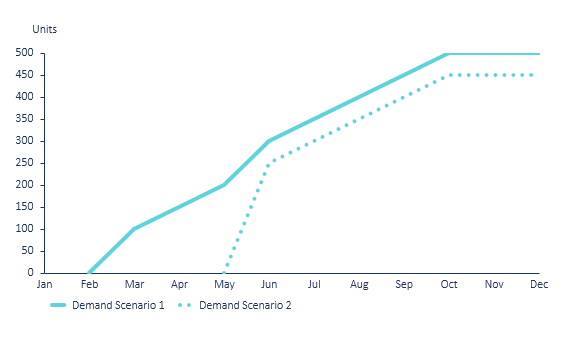

For many products and markets, countless scenarios can be developed that take all possible uncertainties and details into account. However, this is usually necessary to match demand and supply in the S&OP process. Our project experience shows that many scenarios hardly differ; that means their number can be reduced significantly. In a well-defined S&OP process, the demand planners are required to work out the key points in which the different scenarios vary: What are the milestones and timelines for a new product introduction? How does the expected product life cycle look like (adoption curve, expected peak sales, …)? By considering the critical decisions, the number and complexity of demand scenarios can be reduced. This step simplifies subsequent supply planning and S&OP processes a lot. Another important aspect is the cross-functional development of demand scenarios. Getting input from many functions in the organization (e.g., for major marketing campaigns or market entry strategies) and striving for shared assumptions helps to identify the right demand scenarios to submit to supply planning.

2. Assess Supply Options and Supply Impact

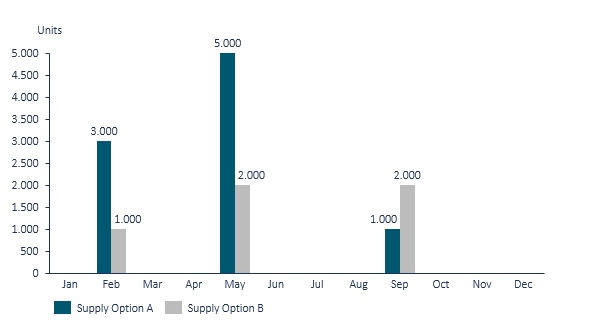

In the second phase, you need to consider how to respond to the various demand scenarios. For this purpose, the submitted scenarios are analyzed by supply planners, followed by developing possible supply options. They develop those supply options with established supply planning methodologies (e.g., rough cut capacity planning). Here, they look at questions like:

- How much capacity is available?

- Do other products have to be allocated?

- What are the stock targets?

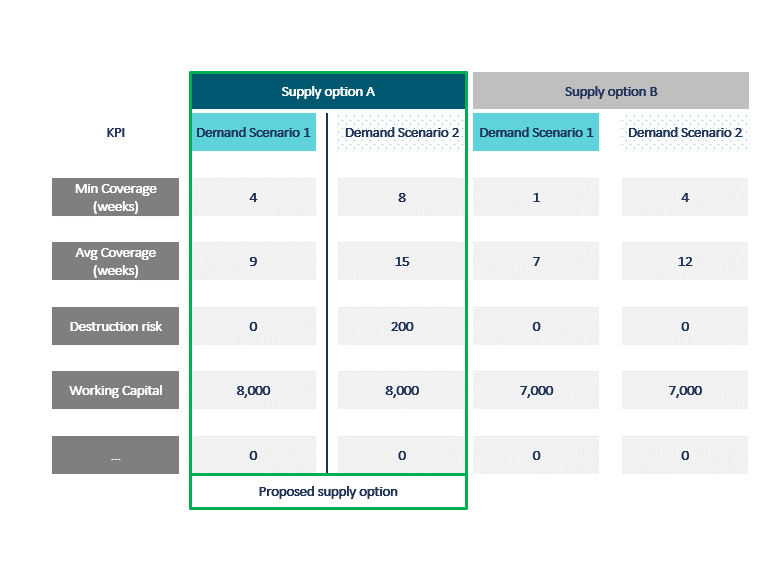

This step will probably result in two to three supply options which are now compared in the so-called supply impact assessment. Here, different demand scenarios are combined with different supply options. This step provides answers to questions like “What happens if demand scenario 1 proves to be true and if supply option B was previously selected?” or “How does the situation differ when demand scenario 2 occurs?” To answer these questions, predefined KPIs will help, e.g., destruction risk, minimum weeks of coverage, average week of coverage or cost of capital, to name but a few. Each business is different and may require other KPIs to be considered. Once all KPIs are available, the demand and supply matching can be prepared in the S&OP process and a proposal be worked out by the supply planning team.

3. Match Demand and Supply in S&OP Meetings

The final and, if everything is well prepared, also the most value-adding step, is the demand and supply matching in S&OP meetings. We recommend to always reserve enough time for this agenda point. The demand planners should present the demand scenarios briefly, concisely, and visually (standardized templates can be used). Then the supply planners present the supply options and the results of the supply impact assessment. Now the proposal can be discussed to decide for one supply option. It is important to encourage the participants in the S&OP meeting to take decisions. The S&OP coordinator should now document the required actions decisions and ensure the execution of those. We advise to briefly review the execution (e.g., in action items) in subsequent meetings to be able to respond to changing factors as quickly as possible.

Our project experience showed that especially countries and markets benefitted from more transparency on the supply situation so better demand planning was possible (e.g., the timing for campaigns). Furthermore, the collaboration between the different functions strongly improved. It even helped to reduce firefighting activities and unnecessary escalations to senior management for decision making as planners were enabled to take decisions.

Thoughts on How to Establish the S&OP Scenario Cycle

The S&OP scenario cycle aims to be pragmatic without over-simplifying matters: It includes input from other functions and does not over-engineer scenarios. This follows a logic where scenarios are detailed when it comes to the considering information that would impact demand with high likelihood e.g., planned marketing campaigns. It refrains from creating too many scenarios, e.g., for each identified driver. A strong focus on the essential information and not on the smallest demand differences is key.

For the implementation we advise to regard the process as a journey. There is no need for a perfect setup directly from the beginning. Start small and improve continuously. With more cycles and experience, standards can be set, and people learn what decision makers need to make an informed decision.