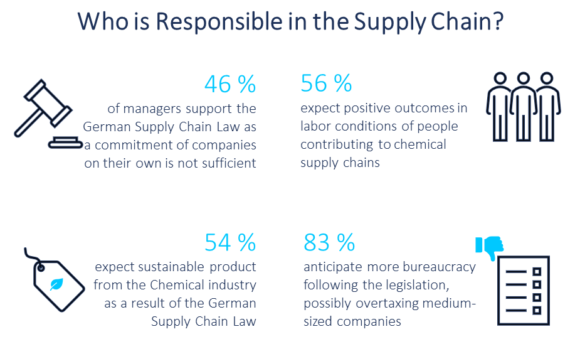

The Supply Chain Act is meeting with a mixed response in the German chemical industry.

The German Supply Chain Due Diligence Act, or Supply Chain Act for short, (Lieferkettensorgfaltspflichtengesetz or Lieferkettengesetz) has significant effects on the chemical industry in Germany. This is evident from the CHEMonitor 2/2021 trend barometer published by CHEManager and CAMELOT.

Pros and cons of the Supply Chain Act in the chemical sector

Support for the Act’s purpose

Four out of five people surveyed from the chemical industry hope for better working conditions for the people who work in companies within the supply chain for chemical products. More than half of the survey participants (57%) confirm that voluntary commitments made by the chemical industry to date are not sufficient. From this, it is evident that there is essentially widespread approval for the Act’s purpose.

82 percent of the companies surveyed with more than 3,000 employees also indicate that they have already implemented some of the future measures.

Concerns in detail

However, when it comes to actual implementation, those surveyed in the chemical sector express concerns: 83 percent of the survey participants fear that the additional bureaucracy will ask too much of SMEs in the supply chain in particular. Companies with fewer than 1,000 employees are of the view that they will be expected to do a great deal of work to amass the information. In some cases, they doubt whether they will even be able to afford to procure the information.

There are also legal and technical concerns: Fifty-eight percent of the study participants from the chemical industry expect legal uncertainty for their own company with respect to liability. In addition, around half of those surveyed fear that smaller suppliers will not allow themselves to be audited or that the publication obligation contravenes existing contracts. 55 percent fear that they may not find any alternatives for critical suppliers.

Key points of the Supply Chain Act

The Supply Chain Act obliges all companies to prove social and environmental compatibility in their supply chains. Alongside their own organization, chemical companies have to audit their direct suppliers (tier 1). German chemical companies have a duty of care for indirect suppliers.

What obligations and bans apply?

The Act cites these bans and obligations specifically:

| Bans | Obligations | |

| Human rights |

|

|

| Environmental protection |

|

|

Which companies are affected by the Supply Chain Act?

The Supply Chain Act applies from 2023 for companies in Germany with over 3,000 employees, irrespective of the sector. In addition, the Act applies from 2024 for companies in Germany with more than 1,000 employees.

Does it only affect German companies?

The Supply Chain Act initially affects only companies with more than 3,000 or 1,000 employees respectively in Germany. However, the EU is following suit: A Europe-wide regulation governing duties of care in the supply chain is currently being developed.

How are contraventions of the Supply Chain Act punished?

Companies contravening the Supply Chain Act face the threat of fines. They can amount to up to 2 percent of the global annual turnover. In addition, companies may be excluded from the awarding of public contracts.

The German Federal Office of Economics and Export Control is responsible for checking whether the Supply Chain Act is being complied with. It investigates contraventions, inspects reports, and checks whether omissions are being resolved.

What does the Supply Chain Act mean for chemicals?

What do chemical companies need to do?

The Supply Chain Act gears supply chains toward sustainable business models and takes account of compliance with human rights in the supply chain. To comply with the Supply Chain Act, chemical companies need to be active in nine areas:

- Set up risk management for their own company and direct suppliers

- Establish passive risk monitoring for indirect suppliers

- Adopt a human rights strategy for the company

- Anchor preventative measures for the company itself within processes and define supplier-specific measures

- Develop a concept for remedial measures in the event of contraventions (for the company itself, direct suppliers, and indirect suppliers

- Ongoing documentation with respect to compliance with duties of care

- Annual report about the fulfilment of duties of care

- Establish a complaints process

- Define responsibility for risk management

The blog article “The Supply Chain Act and sustainable transformation of the supply chain” demonstrates opportunities for sustainable reorganization of the value chain.

How should chemical companies check their suppliers?

Companies need to set up risk management for their own company and direct suppliers. The Supply Chain Act links this with regular reporting.

For direct suppliers as of tier 2, the Act prescribes risk monitoring. Companies to which the Supply Chain Act applies must not only investigate indications of contraventions but also take action: for instance, create a risk analysis, develop and monitor a concept for handling the issue with the supplier in question, and determine preventative measures. Supplier questionnaires or reports are also conceivable to ensure that suppliers are not contravening human rights and are complying with environmental standards.

What are the first steps for chemical companies to take?

In an initial step, chemical companies should

- adapt their risk management to the requirements of the Supply Chain Act

- prepare a human rights declaration

- establish proof of duty of care obligations with suppliers

- prepare changes to the organization, process and, where necessary, technology for documentation and reporting

You can find further recommendations for action in relation to the Supply Chain Act here.