In the last years, many new logistics technologies have been developed and are now available on the market. Given this number of technologies many companies are overwhelmed with defining a target picture of their future warehousing strategy up to five years or later from now. In this blog article series, we guide you through new industry insights, enriched by our observations, experience, market research and project insights.

The first article will take a closer look at one of the core innovations for digital warehouses that Gartner identified in their latest Hype Cycle for supply chain execution technologies: warehouse picking (humanoid) robots.

Use cases for Warehouse Picking (Humanoid) Robots

We understand the innovation of warehouse picking (humanoid) robots as a combination of modern technologies: artificial intelligence (or more accurately deep or machine learning) and computer vision systems for collision, horizontal body movement, flexible arm placement as well as gripping techniques. The blend of these technologies allows robots to act collaboratively, move without guidance in changing environments and pick varying items.

While factors like growing computing capabilities and dropping robot arm prices lead to an overall price decrease for robots, warehouse picking robots can be seen being very limited towards their usability in specific cases (such as palletizing) with consistent conditions. At the current state they are too inflexible and large for a multi-task orientation in warehousing. In most cases humans will outperform warehouse picking robots.

Results from Market Research

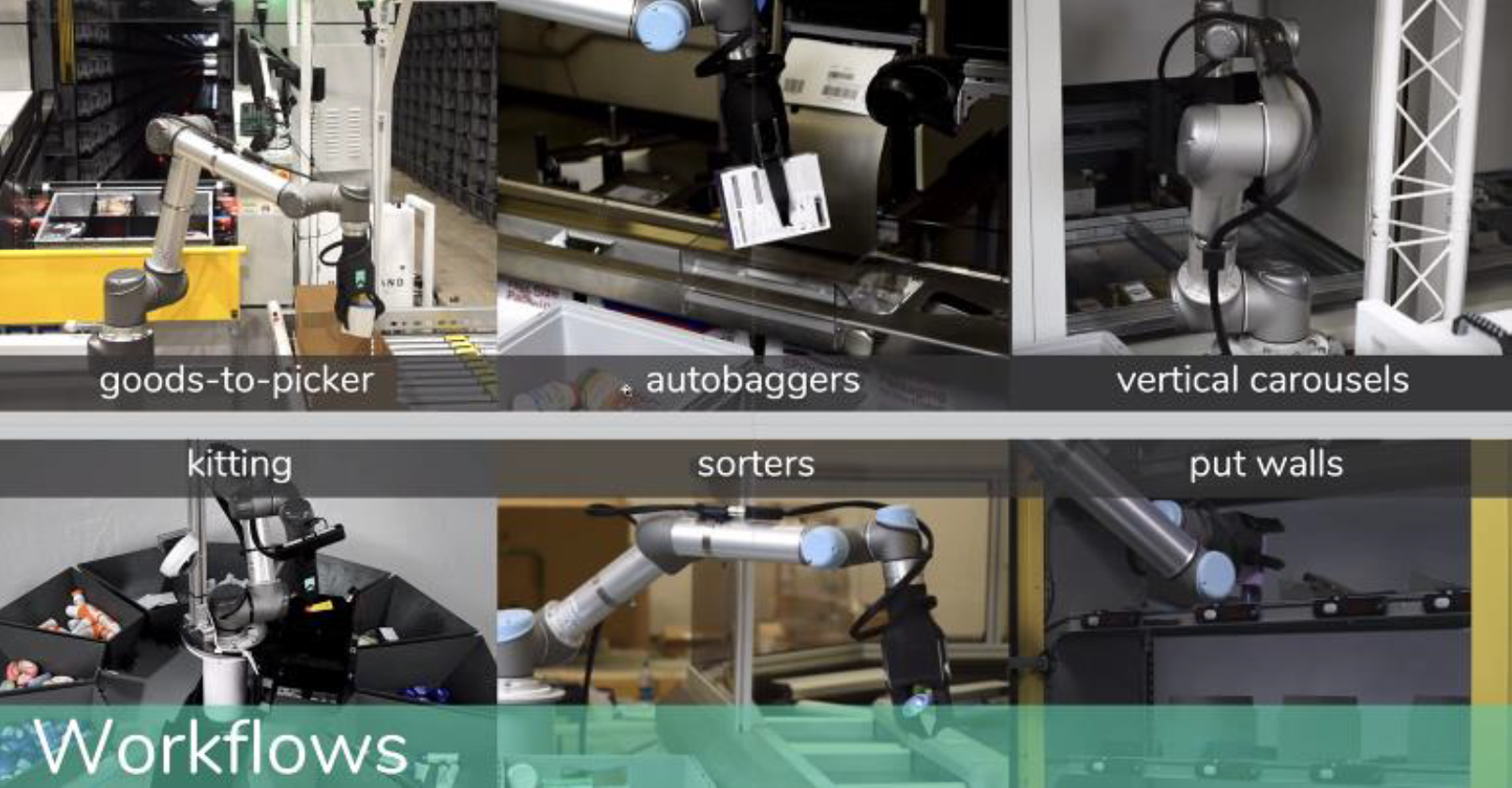

Our market research on AI solutions in warehousing has shown that there is a variety of warehouse picking (humanoid) robots. Some possible capabilities performed by such robots are shown in the picture below:

Potential workflows of Righthand Robotics [1]

The flexibility, the use of current technology and the autonomy of provided solutions is ever-increasing. You can find both autonomous immobile picking robots and collaborative commissioning robots. The innovation of autonomous mobile manipulating robots (AMMRs) comes closest to a human and the corresponding capabilities. They can access shelves independently and transport goods to picking stations or assist with picking, resupply, returning to storage, regular counts, sorting and unpacking. By using artificial intelligence and machine learning they can identify new potentials for efficiency. In some cases, these robots can be set-up within 15 minutes. In addition, robots-as-a-service is becoming a trend in solutions provided.

How CAMELOT rates this trend

At CAMELOT, we see enormous potential in warehouse picking (humanoid) robots and/or autonomous mobile manipulating robots. The increasing flexibility and adaptability suggest that even outside of consistent environments these robots can be used to either assist or take-over tasks performed by employees, while steadily improving their performance through self-learning methods. In warehouses with robots, employees will either work or be assisted by them. This will allow the employees to focus their attention on the key value-added tasks.

We recommend considering autonomous mobile manipulating robots in combination with warehouse picking robots in your future digital warehousing target vision. Their mobile character means that they can be used, for example, in both incoming and outgoing processes and compensate fluctuations. So far, we see warehouse picking (humanoid) robots are a feasible solution for warehouses with consistent environments and the cost of human labor is a useful indicator of your decision. At this stage, the use of AMMRs is only feasible within a warehouse with sufficiently high throughput, high complexity and/or delivery time dependency, such as distribution centers for branch supply or e-commerce centers.

Conclusion

Leveraging innovations like warehouse picking robots requires you to align either your processes, your business, or your IT strategy accordingly. For the specific example, in addition to the IT infrastructure employee acceptance plays an important role. The benefit may outweigh the risk by leading to increased efficiency, optimization of processes and resource utilization or reduced costs. CAMELOT provides you with insights, experience, and guidance on how and whether you can apply these innovations.

To find out more on the possibilities in digital warehousing, we invite you to turn to CAMELOT´s market research on AI in warehousing. If you want to know more about additional AI-driven innovations or the integration of innovative technologies into your digital warehouse future vision, contact us.

We would like to thank Thomas Grill and Albert Peychal-Heiling for their valuable contribution to this article.

[1] Screenshot taken during the online presentation of Schechter (02.04.2020).