In their Hype Cycle for Supply Chain Execution Technologies, Gartner highlights the growing importance of simulation and modelling capabilities for supply chain network design. In particular, there are several use cases in the area of digital twins. In this blog article you will learn more about Supply Chain Execution Systems and how they relate to Supply Chain Network Design.

Digital Twins in supply chains

Many organizations are currently investigating the potential of Digital Twins in supply chains. Their implementation can be a stand-alone solution or even become part of a whole supply chain transformation. At CAMELOT, we assume that Digital Twins will be affecting Supply Chain Network Design in general and especially support procurement processes.

How Digital Twins can be used in Supply Chain Network Design

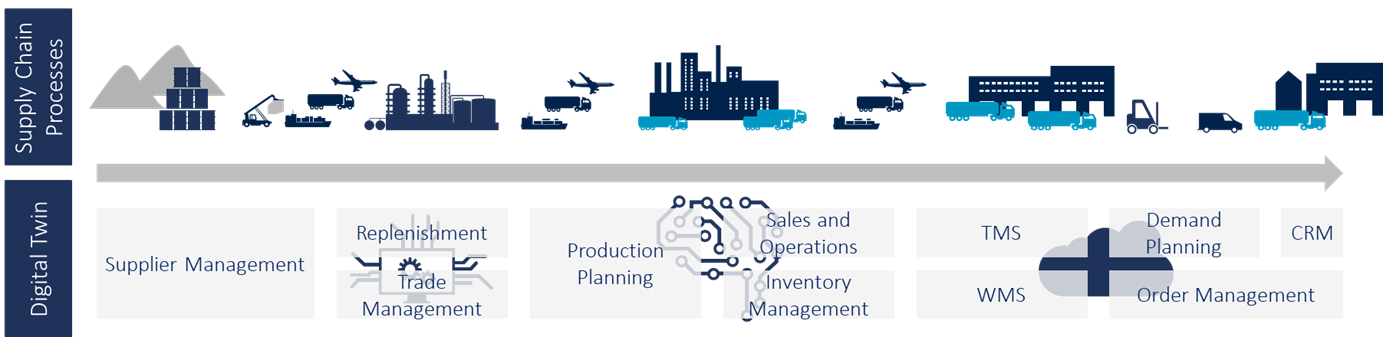

As a result of current developments in a digital world, such as higher computing power and the linking of data from a wide range of sources, new potentials are emerging in several areas across the supply chain, particularly in data analytics. In many production facilities, digital twins of machines have been in use for several years to tap new potentials through efficiency gains and proactive maintenance work. This approach can also be transferred to other areas along a company’s entire supply chain.

Previous use cases have included a collaborative platform for supply chain design that enables cross-functional as well as cross-regional work on improving the supply chain set-up. For example, this platform made it possible to test the effect that a local optimization in Europe would have on replenishment transports from American production facilities.

It is now possible to interlink many use cases from different functions on a single platform, such as planning or logistics purchasing, and to connect them to a single data model that is available anytime online with a user-friendly app that your company can use in a wide range of functions. With the help of these specialized apps, it’s possible to create interfaces to each individual function, integrate work results and make better, more holistic decisions.

Digital Twins in Logistics Procurement

In this blog article, we are focusing on the topic of logistics procurement. In the context of potential tenders for logistics services, a digital twin makes it possible to quickly evaluate necessary data and prepare it for new award scenarios. The new technical possibilities support the tender process in preparing and analyzing potential effects on the supply chain, among other things. Two core areas can be identified.

Analysis of tenders

The first area where a digital twin can replace existing processes and systems is the analysis of tender results using an analytics platform. Many of the established platforms for tender management support focus on transport services, which means that only part of the supply chain is supported. Warehouse activities, on the other hand, are in many cases difficult to manage with standardized platforms due to their special requirements.

Established analytics platforms can analyze results and offer the benefit of standardized communication interfaces and integrated provider databases. In many cases, however, service providers are already pre-qualified for tenders. This results in a portfolio of suppliers, which over time allows for a potential rotation of contracted service providers. However, applying rate tables from a range of different providers limits the flexibility of standardized platforms. Digital twins offer significant advantages in these processes: quick analysis of offers in a tender as well as direct simulation of details with each respective provider. For example, a digital twin makes it possible to display and evaluate warehouse processes such as reworking or repackaging, whereas analytics platforms usually only deal with rates and volumes. This quickly provides a meaningful result that can be used for comparison. There are indeed additional costs for the new digital twin platform. However, if the costs of different platforms are bundled in a digital twin, in most cases it’s possible to not only increase the range of functions, but save on licensing and usage costs as well.

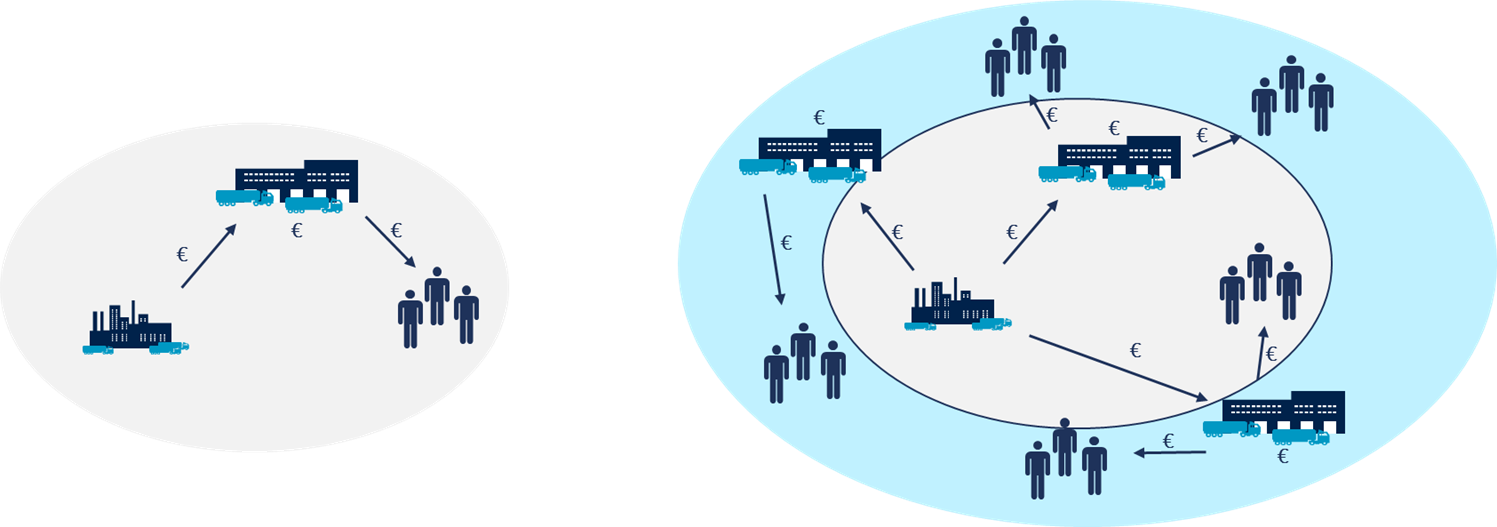

Improving the setup of the entire supply chain

The second area is the impact of a tender on the entire supply chain setup. With a digital twin, it’s possible to quickly analyze scenarios that have not yet been considered. These include

- supply of regions and customers in border areas between two warehouses

- effects of changing rates in a warehouse or for distribution to a specific area

- effects on the total cost of products in other warehouses created by partial transport tenders on the last mile in a warehouse or between locations

- changed replenishment patterns in demand scenarios and their impact on total costs in different warehouses

- reallocation of warehouses or production site location changes

- environmental conditions, such as new legal regulations or agreements between countries

Overall, digital twins make it possible to make more holistic, transparent decisions in supply chain management. Decision-making becomes much easier than it has been in the past. You can be sure that no individual parts of the supply chain make improvements that would result in additional costs elsewhere, e.g. in replenishment transports or warehouse handling – aspects that are not considered in an isolated tender.

We would like to thank Tim Walde, Dominik Hartung for his valuable contribution to this article.