Global logistics visibility is a trend in logistics that we can expect to take the threshold to a wider acceptance within the next years. Organizations will not gain from visibility alone, however. Data availability and integration will need to be achieved as well to leverage the full potential with visibility solutions. Here, technology still poses challenges.

In this blog post we discuss three areas to focus on for successfully implementing visibility.

First focus: business benefit

Before considering the technology, it is essential to develop a clear vision how visibility contributes to your future supply chain strategy. Starting from this high-level point of view is inevitable for choosing the right technology approach which integrates with your supply chain in general. For one company, visibility is the key lever for reducing inventory by moving closer to just-in-time operations and at the same time reducing the inherent risk by closely monitoring stocks in transit. For a second company, responsiveness, and reliability with the background of increasing customers’ requirements need the visibility focus specifically on order fulfilment. Do you have a clear record what visibility will contribute to the specific needs of your supply chain?

When embarking on the journey to supply chain visibility, the route needs to be defined by tangible intermediate targets. Thus, the vision is broken down to specific benefits to be addressed and structured along the supply chain, e.g. by different product groups. At CAMELOT we have experienced that use cases provide a feasible division of an overall picture which also relate to best practices derived from other installations. This structure puts benefits relevant for your business first and avoids putting effort into non beneficial aspects of the supply chain with a technology which may be highly complex.

The first point on your visibility agenda should be the vision and the use cases. Visibility might fuel scenarios as anti-counterfeiting, returns management, condition monitoring (such as temperature for a cold chain) or serialization (e.g. for pharmaceuticals or safety critical automotive parts). Even using real-time visibility in scenarios with lower complexity, e.g. a single transport, you may find benefits in earlier reaction on deviations, reduced waiting times, improved utilization, and reduced service labor. Improving customer satisfaction, certifying an origin, increasing responsiveness, or promoting performance are targets which relate to many of the use cases contributing to overall visibility.

Find some examples use cases in our blog:

https://blog.camelot-group.com/2020/07/supply-chain-visibility-in-automotive-logistics-a-use-case/

https://blog.camelot-group.com/2020/07/supply-chain-visibility-in-food-logistics-a-use-case/

Second focus: business integration

Knowing the exact arrival time of a truck could mean everything if you depend on a 15-minute time window for a just-in-time production. On the other hand, if you just fill up your stocks on a regular basis, it might simply not matter if the truck arrives one day later. So, visibility information depends on the context of your supply chain execution. And it can only generate value if the information arrives in the execution environment and triggers a reaction. Obviously, the information does not only need to be accurate but

- it must be timely to leave options for any decision to be made,

- it must trigger the attention of the right role in the organization to take the decision, and

- it must link to all other information relevant for the decision.

Only then the delay of the truck does not cause a full standstill of your just-in-time production.

Thus, visibility goes beyond monitoring times, delays, status, events, and confirmations. The solutions on the market provide status lists, alerts, and overviews, even including exact positions on maps. But only with integration of the systems back into the execution processes, an event will trigger a decision. With data-driven decision making, a value is created from visibility. At Camelot, we put this value into focus. Before implementing visibility, you need to understand the decisions which you are making and which you want to be able to make. Investing further would consequently lead to decision automation – but this will be a topic of its own.

Third focus: data integration

Of course, not only the integration providing visibility information to execution processes is necessary, also the other direction of collecting all relevant data from execution to gather visibility information is essential. So, the next step is to address the technological challenge remaining.

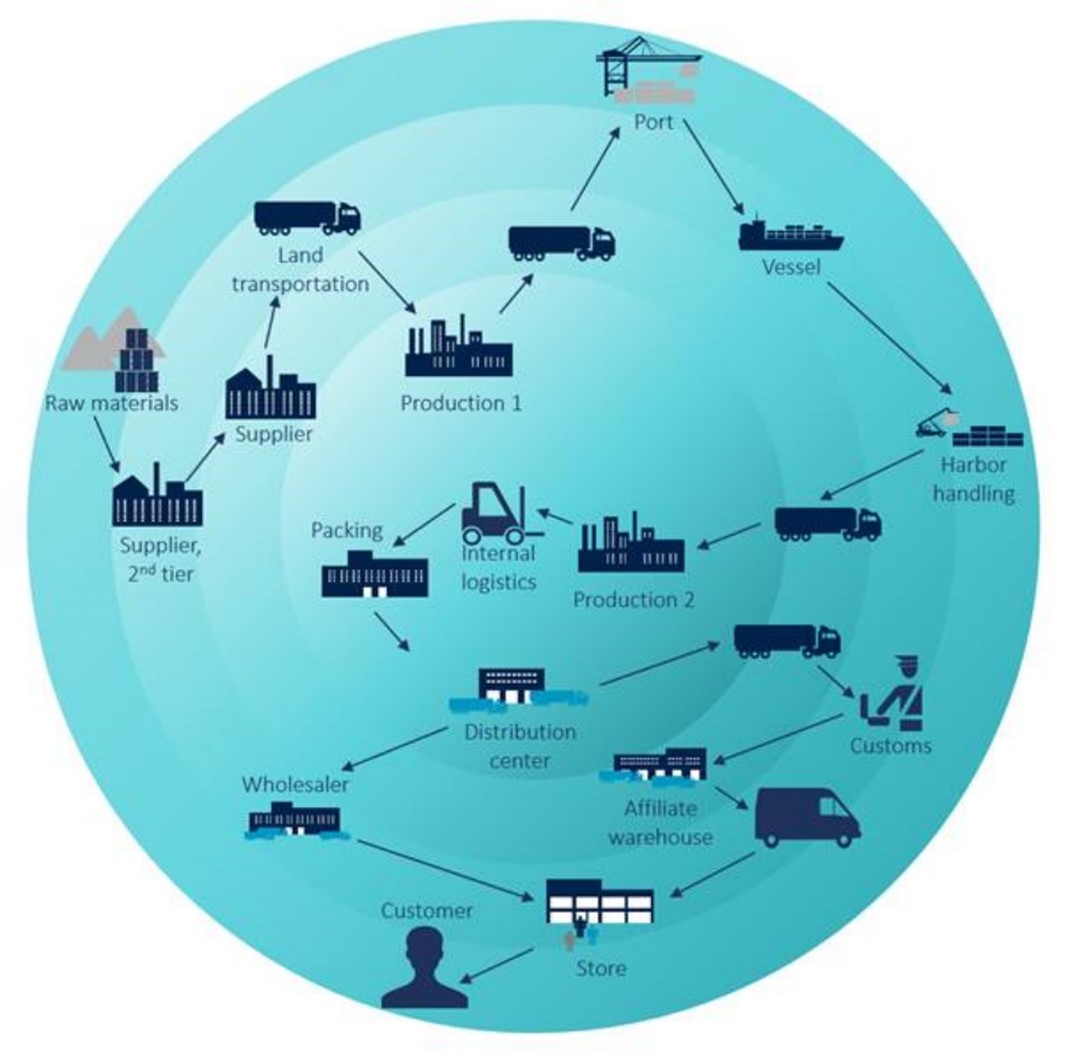

There is a multitude of data sources for visibility, ranging from the documents controlling supply chain execution in your own systems (purchasing, stock management, order fulfilment and transport), to systems of your direct partners, providing confirmations, status, and events to you. Receiving information standardized in format and interpretation is a challenge you may already have mastered. But still not all your partners may be open to share all the information for the full transparency you would prefer. Your partners’ partners, involved in fulfilling their part of the execution of your supply chain, are typically not fully known to you, let alone being directly connected and providing data to you. And as soon as your supply chain grows more complex, more and more partners are not visible to you at all. Availability of data obviously needs to involve service providers who operate a network and connect you across all relations.

Data sources along the supply chain have different degrees of accessibility – from your own execution to network participants with only indirect contact

There are two technology approaches to this challenge in general: On one hand connectivity platforms provide access to a network of many partners as a basis of sharing information. On the other hand, IoT devices allow to collection of data independent of actual physical handling the goods. Besides position data they also allow a close monitoring of conditions (e.g. temperature or humidity to manage product quality, as well as large acceleration to control the origin of damages) and extend visibility to many parameters. Choosing the right combination of data sources will be the basis for visibility across your complete supply chain.

And once the data sources are defined, further steps need to address standards for data as well as a critical evaluation of the data quality.

We would be glad to discuss your own need of visibility with you and attend you on your journey towards the benefits of visibility.