How to start the journey towards a parameter-driven value chain

In our previous article, we elaborated on how a parameter-driven value chain works and how it generates significant advantages. In particular, we described how it improves transparency, creates flow, helps to master inventory and reduce the bullwhip effect, and how it reduces planning and execution effort. In this article, which concludes our series, we will explain how to start the journey towards a parameter-driven value chain to exploit the benefits.

Parametrizing your value chain: sounds good, but where to start?

Lean Production and Theory of Constraints have added to the planning and execution toolkit beyond what we now perceive as traditional planning methods. Practitioners across industries have widely adopted both approaches. The reason: both provide techniques to improve quality, enable standardization, and increase efficiency. One of the focus areas of these approaches is creating flow by leveraging parameter-driven tools like buffer sizing, defining takt rates, and dimensioning Kanban control loops.

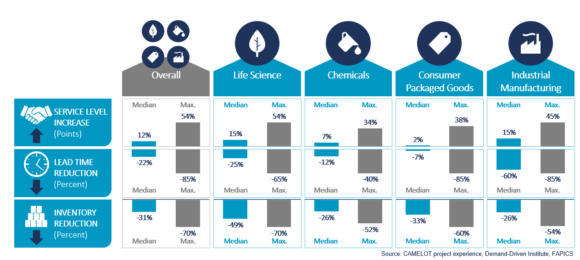

More recently, we have been seeing promising results and inspiring stories about successful Demand-Driven MRP (DDMRP) journeys. For the reader who followed our blog series, this should hardly be a surprise. It is our conviction that DDMRP combines many of the proven elements of Lean and Theory of Constraints. The Demand-Driven Radar 2019, a cross-industry study on DDMRP adoptions, shows significant gains from a demand-driven value chain. Companies across sectors demonstrate to achieve inventory reductions, shorter overall lead times, and increased service levels.

Figure 1: Service level increase, lead time, and inventory reduction owing to the implementation of DDMRP

With the potential benefits in mind, the question is where to start. From our perspective, a shift to a parameter-driven value chain approach can be initiated and executed in different ways. The appropriate way is unique for every company and needs tailoring according to the following aspects.

How to set it up strategically?

There are good arguments for implementing a parameter-driven value chain in a bottom-up way, but the same is true for a top-down approach. A bottom-up approach starts within specific areas, typically driven by the planning and execution practitioners. In contrast, in a top-down approach, the explicit goal to implement a parameter-driven approach is set by executive management guided by specific business targets and often linked to a broader transformation program.

A pure bottom-up approach has the advantage of creating acceptance at the planner level. Still, it could result in a lack of momentum, and the initiative might get stuck if resistance occurs. Success would also be dependent on the local environment and individual sponsors. As these local sponsors are vital for the transformation, a change in support can quickly turn into severe risks for finishing the transformation.

On the other hand, implementing a parameter-driven value chain following a top-down approach may lead to a lack of synchronization with functional needs. Focusing on planning and execution specifics is likely to be too granular to gain executive support so that a link to strategic goals and business benefits is essential.

To overcome the disadvantages of pure bottom-up or top-down approaches, we recommend a combined strategy. From our experience, the chances of a successful transformation are much higher if you can secure both: the understanding and trust of functional managers and the executive-level support and sponsorship. The early involvement of operational experts builds the necessary basis for an appropriate fine-tuning. Also, the management of all local stakeholders is a prerequisite to drive acceptance and process compliance.

This approach’s drawbacks include the risk of failure if not tied to business value or not embedded in the overall operating model. These aspects should be monitored and managed to ensure success.

The general approach to value chain transformation

Understand where you are

The most challenging step is the first one, transforming from traditional Supply Chain Management to adapting demand-driven in operational activities. Therefore, companies need to know their baseline, identify shortcomings, and the value chain’s maturity level. A clear view of the baseline helps to understand requirements and realistic timelines for achieving improvements and the focus areas to build capabilities.

Figure 2: In most cases, the greatest difficulty for companies is getting started, that is, transforming from traditional Supply Chain Management to adapting parameter-driven in operational activities

Change the “thoughtware” before implementation

The approach to drive the transformation journey involves changing the “thoughtware“ to win support in the organization. The “thoughtware” is the underlying set of assumptions on which every organization operates.

To change the “thoughtware,” companies need to create awareness and communicate a clear vision for the parameter-driven journey. After this, curiosity needs to be fostered and served by explaining the value proposition. At the end of this stage, senior management should have been brought into the journey. Finally, to complete the change of “thoughtware,” companies need to create a more in-depth understanding of the new concepts, including leveraging training and certifications.

As part of this required “thoughtware” update, the feasibility of the parameter-driven value chain needs to be evaluated in detail to identify areas and segments for application. In addition, the technical fit of potential solutions to the overall system landscape should be assessed and validated.

As the last step before broader roll-out and implementation, we recommend leveraging limited-scope pilots to grasp the implications of shifting to a parameter-driven value chain and fine-tune the roadmap for further roll-out.

Key areas of a parameter-driven value chain transformation

Typically, one’s perception is biased by prior experience. Therefore, it is no wonder that many transformations are unbalanced, reflecting the background of the sponsors. For example, some transformations focus on defining business cases to generate financial impact but lack the details required to deliver. Likewise, IT-focused implementations overestimate the power of tools and underestimate the drive that personal commitment and focus on common goals can create.

Hence, a transformation approach needs to balance the following elements, always considering the impact that a shift to a parameter-driven value chain will have on each:

- Processes and organization

- People and skills

- Performance management and incentives

- System and tools

Standardization and centralization drive processes and organizational transformation

Making a value chain parameter-driven allows for a higher standardization. In turn, this standardization drives the separation of value chain “planning“ activities that are typically very heterogeneous. The shift to a parameter-driven value chain will affect the following activities in different ways:

- Supply Chain Planning: short-term and tactical planning can be centralized as standardization and digitization make this possible. Typically, this leads to changes in resource allocation, role profiles, and organization design.

- Supply Chain Parametrization: in a parameter-driven value chain, it is critical to strive for excellence and consistency in parameter definition and adjustments. Whereas supply chain planners execute parameter changes, the supply chain parameterization team defines the overall framework, drives excellence, and embeds best practices in supply chain processes. Think of it as a Center of Excellence. These activities are typically centralized.

- Automated Supply Chain Execution: many execution activities, like replenishing a local buffer, can now be automated, resulting from standardization. This automation increases process compliance and makes central control easier.

- Local Supply Chain Execution: depending on the level of process automation and relevance of local specifics, some activities like order checks and alert and exception handling remain for local staff to be performed, but on a smaller scale than in the past.

Overall, a shift to a parameter-driven value chain drives centralization and an efficiency increase.

A so-called Control Tower process is a particular example of the impact of a parameter-driven approach. This process helps to bridge between central and local perspectives and to balance global targets and local requirements. Parameter-based automation can standardize and centralize decisions, thus reducing the need for manual alignment.

Process and organizational changes require building new skills

The new way of working requires the promotion of proactive planning instead of focusing on firefighting. Attention needs to shift from a pure cost focus to promoting flow.

Leveraging the potentials of a parameter-driven value chain will help an organization to overcome the typical silo mentality. Instead, cross-functional collaboration can and has to be ensured. Otherwise, the synchronization potential cannot be reaped. To address this challenge, companies need to promote parameter-driven concepts beyond the boundaries of the supply chain organization.

Moreover, standardization and centralization will increase resource flexibility because standardized tasks require less highly-skilled and experienced resources. Also, the training of new resources will be easier and more efficient.

Overall, there needs to be a shift to a holistic view and systems thinking, and continuous improvement. These changes are enabled by the clear separation of supply chain layers and horizons, as explained before.

Align people by using appropriate incentives

Intended behavior needs to be managed to realize the potential of a parameter-driven transformation, which is often a considerable challenge. Company performance is driven by delivering value to the customer. Thus, an end-to-end optimization of the processes is relevant, not silo optimization based on functional metrics like unit cost. These typical pitfalls of conventional supply chain metrics systems need to be addressed.

To counter the shortcomings of traditional metrics, companies should focus their metrics on flow. This approach improves alignment between targets and incentives, especially when moving to a parameter-driven supply chain.

Flow is an excellent target to align metrics because it is a conflict-free objective of a supply chain. After all, flow improvements across various performance dimensions consistently increase ROI. More specifically, the focus on flow enables improvements in the following :

- Service: flow supports achieving customer service expectations.

- Revenue: meeting and overachieving customer expectations will result in higher margin potentials and/or higher market share.

- Inventories: a flow orientation, e.g., focus on higher turns or smaller lot or batch sizes based on a parametrized supply chain in line with actual customer expectations, reduces the required inventory as well as work in progress.

- Expenses: flow in accordance with customer expectations reduces the need for expedite shipments, short-term capacity increases, or rescheduling. As a result, associated costs will decrease

- Cash: cash-to-cash cycle times improve as the parameter-driven chain better syncs with customer requirements and reduces working capital as well as expenses

Carefully select suitable systems and tools

Finally, systems and tools need to support the journey. The proliferation of cloud computing and open interfaces leads to an ever-growing landscape of solutions. Therefore, companies should keep an eye on new, promising solutions that are constantly challenging the incumbents in the planning and execution space.

What to expect when?

A transformation towards a parameter-driven value chain is a multi-year journey. Think of a marathon instead of a sprint. New ways of working and paradigms need their time to trickle down the organization. Consider the classical waves of change management: there will be resistance, and there will be failures. Both will challenge the transformation. Therefore, it is essential to set and manage the expectations in a holistic yet dynamic way and manage the timeline.

Companies need to define a desirable and motivating target state to align the organization, often called the “North Star.” Take the effort to define it and make sure to communicate it so that key stakeholders of the transformation support it. Apart from specific quantitative targets, it is crucial to create a mutual agreement on the direction of travel. Make your organization want this change. Numbers can easily change as the next downturn or industry disruption may loom. Also, keep track of the support in your organization, leveraging available tools to monitor engagement. Of course, you should also monitor and manage target achievement to build trust.

So, what do you get?

After our in-depth explanation of how to approach a parameter-driven transformation, let us recap and break down why you should start such a journey in the first place.

When you have transformed successfully, you will have gained the following benefits:

- a centralized planning organization,

- a consistent E2E parametrization process,

- the readiness to master future challenges,

- improved value chain capabilities,

- the foundation for leveraging machine learning and virtual planners,

- freed capacity, enabled by strongly reduced firefighting, and

- overall, a dramatic performance boost of your value chain.

Conclusion

This series explains why a parameter-driven value chain is relevant and important (part I). We provided insights into why and how a parameter-driven value chain works and what type of benefits you can expect (part II). We then elaborated on the benefits. We showed how a parameter-driven value chain enables transparency, how it creates flow, limits the bullwhip effect, and reduces planning efforts while improving planning quality (part III).

In this last post (part IV), we provided advice on starting a parameter-driven journey and reaping the advantages. We showed what benefits other companies have achieved and investigated what strategic approach to consider, i.e., top-down or bottom-up. We emphasized how essential a change in “thoughtware” is.

Also, we explained the critical impact areas of a parameter-driven transformation and what will change, i.e., standardization and centralization, and how this drives the process and organizational transformation. We also described some of the newly required capabilities and the need to align people by using appropriate incentives.

A shift to a parameter-driven value chain is a promising endeavor. However, as with every transformation, it is of utmost importance to set up the transformation in an ambitious yet realistic way. All levels of the organization are relevant to make the transformation a successful one. This change needs to be shaped and managed. As the benefits of parameter-driven value chains are comparatively tangible and straightforward to communicate, companies should take up the challenge and upgrade their value chains to a new level now.

How to slice it?

We have shown how to strategically approach a transformation, and we have outlined what the aspects will be. Now the question is how to slice and dice a parameter-driven transformation to get going. Given that you cannot transform your complete value chain at once, we provide some pointers on where to focus and extend the scope step-by-step.

Value chains

Do not start with a value chain that has critical performance issues. Also, do not choose the most complex one. The guiding principle is to select the value chains with a broad range of elements and characteristics in common with other value chains. In doing so, companies can leverage insights. Also, consider that it is critical to start with success, so the problematic cases should be tackled when you have learned your lessons. But of course, the general applicability of the parameter-driven value chain approach for your difficult value chains needs to be verified before-hand – unless, of course, you want to differentiate your operating model and establish two different “worlds“ in the future. From experience, most companies try to avoid this for obvious reasons.

Products

Choose representative products and make sure that the products selected can be separated from the rest of the value chain regarding planning, resources, inventories, and processes. Otherwise, the transformation will become much more complicated.

Systems

Even though the drive for automated solutions is ubiquitous, we urge companies to avoid the typical trap of automating pre-mature processes using inappropriate systems and tools. Alternatively, we recommend the use of pilots with reduced functionality. For instance, a pilot may predominantly use manual data integrations to provide critical input data.

Make sure that the promise of automation and higher quality remains realistic. To facilitate that ambitions and reality stay in connection, companies can follow a phased approach that typically focuses on critical features first and then adds non-critical features. Criticality has various dimensions, including business benefits, technical necessities, and user experience.

Regions

Start with a region that can be separated to reduce complexity. Keep in mind to involve other regions involved in the transformation to drive and maintain support. Make the starting region a role model to create pull from the regions not yet involved.

Functions

Remember that the parameter-driven value chain transformation is not just a value chain, supply chain, or operations thing. As the operating model and ways of working will change, so will the interfaces and cross-functional processes. Ensure that up- and downstream processes are appropriately connected and ensure that supplier and customer functions and stakeholders are involved in transformation governance, concept creation, and actual project work.

More insights:

The Parameter-Driven Value Chain, Part I

The Parameter-Driven Value Chain, Part II

The Parameter-Driven Value Chain, Part III

We would like to thank Sebastian Hild for his valuable contribution to this article.