With the COVID-19 crisis and an advanced offer of digital platforms, supplier collaboration is moving again into the spotlight. A successful supplier collaboration promises value for both parties. However, it is often unclear what exactly the patterns of value are and where it comes from. Therefore, we want to delve deeper into the value perspective of supplier collaboration and outline its drivers.

What are the types of supplier collaboration?

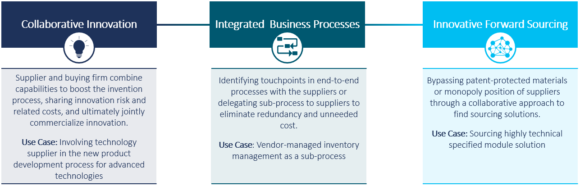

The paradigm change in procurement from cost-driven to value orientation, started already a couple of years ago. Most industries experience a greater pace of business and the urge to respond faster to new market demands or disruptions, including decreased in-house expertise through shifting value creation. This results in buyers being more dependent on their suppliers. Consequently, procurement has to adopt a value-adding position. A major contributor to value-orientation is supplier collaboration. The idea of supplier collaboration is based on joint activities to increase the capabilities in areas such as cost management, supply chain optimization, or innovation. The supplier typically benefits from a faster order-to-cash cycle and better capacity utilization. However, supplier collaboration is mostly limited to strategic suppliers, identified by a multidimensional segmentation not only by spend. We see three distinct types of supplier collaboration:  Figure 1 – Supplier collaboration has different forms depending on the business target Collaborative Innovation: The idea is to mutually profit from each other’s capabilities to drive innovation, and additionally share associated risks and costs. After the joint development, both parties agree on a go-to-market strategy and aim for long-term competitiveness on the market. A common first obstacle is to find the right teaming, along with hurdles like missing prioritization in daily business, communication, and organizational governance. Moreover, suppliers often fear the potential exploitation of knowledge and resources. Integrated Business Processes: Buyer and supplier integrate processes to optimize the supply chain. The depth of supplier integration highly depends on the selected processes and technical readiness. This ranges from automated delivery order at a certain stock level or according to the maintenance schedule. Indeed, taking a view on end-to-end processes, like make-to-inventory or forecast-to-schedule, identifying the touchpoints, and defining a seamless process with the supplier has a lot of potential. With new technologies and digital platforms, suppliers can easily be integrated into processes at low switching costs. For example, real-time automated planning updates in inventory and demand management facilitate incorporation of suppliers into the warehousing process. Nevertheless, transparent end-to-end processes are required, as well as the right technological enablers. Innovative Forward Sourcing: Complex module sourcing processes or patent-protected components often seem like a dead end. Achieving the technical and commercial requirements due to a potential supplier’s monopoly position or missing existence on the market is a common hurdle. Here, it is advisable to find a forward sourcing solution collaboratively with the supplier. Hence, the technical functionality of the component is jointly broken down into elements to bypass patents or monopoly positions. Consequently, the elements are assessed to find a solution for the component with matching functionalities but a lower price. Often, it is hard to identify a suitable supplier. Therefore, we recommend a pitching round for the solutions from the supplier with a defined project team.

Figure 1 – Supplier collaboration has different forms depending on the business target Collaborative Innovation: The idea is to mutually profit from each other’s capabilities to drive innovation, and additionally share associated risks and costs. After the joint development, both parties agree on a go-to-market strategy and aim for long-term competitiveness on the market. A common first obstacle is to find the right teaming, along with hurdles like missing prioritization in daily business, communication, and organizational governance. Moreover, suppliers often fear the potential exploitation of knowledge and resources. Integrated Business Processes: Buyer and supplier integrate processes to optimize the supply chain. The depth of supplier integration highly depends on the selected processes and technical readiness. This ranges from automated delivery order at a certain stock level or according to the maintenance schedule. Indeed, taking a view on end-to-end processes, like make-to-inventory or forecast-to-schedule, identifying the touchpoints, and defining a seamless process with the supplier has a lot of potential. With new technologies and digital platforms, suppliers can easily be integrated into processes at low switching costs. For example, real-time automated planning updates in inventory and demand management facilitate incorporation of suppliers into the warehousing process. Nevertheless, transparent end-to-end processes are required, as well as the right technological enablers. Innovative Forward Sourcing: Complex module sourcing processes or patent-protected components often seem like a dead end. Achieving the technical and commercial requirements due to a potential supplier’s monopoly position or missing existence on the market is a common hurdle. Here, it is advisable to find a forward sourcing solution collaboratively with the supplier. Hence, the technical functionality of the component is jointly broken down into elements to bypass patents or monopoly positions. Consequently, the elements are assessed to find a solution for the component with matching functionalities but a lower price. Often, it is hard to identify a suitable supplier. Therefore, we recommend a pitching round for the solutions from the supplier with a defined project team.

What delivers value in a collaboration?

From our perspective, the value within supplier collaboration lies in four sub-dimensions. In the following, we will describe the four dimension, which provide value either independently or in combination. Concluding, we will discuss three key enablers for all kinds of supplier collaboration.  Figure 2 – The value of collaboration is derived from multiple dimensions

Figure 2 – The value of collaboration is derived from multiple dimensions

Value

The first pattern of value is innovation itself. The benefits of innovation are numerous, be it increased market share, new market access, cost reduction, or an improved product portfolio. As the innovation is jointly developed, both parties will profit, generally through business growth or increased competitiveness. The second sub-dimension of value is increased productivity. With seamless end-to-end processes, the lead time is reduced, thus resulting in lower warehousing and transportation costs. For instance, the supplier could be incorporated or even delegated to manage the entire warehousing process to eliminate redundant work. Third, resilience is currently of particular importance. Supplier collaboration helps to manage risk better with higher visibility, velocity, and flexibility of the supply chain. Together, potential disruptions can be assessed proactively, and contingency plans to ensure material flow can be developed. Besides, companies benefit from lower inventory costs and increased service level agreements. Lastly, supplier collaboration is a great contributor to sustainability, which has two aspects. On the one side, jointly working on transportation and production solutions helps to effectively reduce emissions. On the other side, regulations like the “Lieferkettengesetz” in Germany require transparency along the supply chain concerning the ecological and social dimensions. Consequently, suppliers are involved in strategies to become transparent in these dimensions, like child labor or carbon footprint.

What enables successful collaboration

We have identified three major enablers to establish a fruitful supplier collaboration regardless of the type. At first, a successful collaboration is built on the right degree of transparency. Therefore, a bidirectional flow of information is inevitable to find the best common solution. This does not mean that suppliers have to share all kinds of sensitive information, like design or cost structure. To avoid legal consequences at a later point, the supplier and the buying firm should agree on shared patents or intellectual property in advance. These agreements should also cover the period, geographical distribution, and possible exclusive claim. Second, a high level of mutual trust in each other’s competencies and confidence to achieve the mutual goal is a key driver. To check whether the supplier is qualified or not, the supplier performance management should provide insights about important KPIs like audit score, their commitment to a long-term relationship, or innovativeness. Regular two-way feedback including all stakeholders helps to foster trust and thus the relationship. Generally, trust is the prerequisite to finding a solution without compromising. Apparently, it is not possible to collaborate with every strategic supplier as they might not be compatible to collaborate with the buying firm. Before approaching a supplier for collaboration, the potential cultural fit has to be ensured. Consequently, both the purpose as well as the business objective must be matched and aligned. The purpose illustrates the fundamental belief, which is shared with the collaboration. The business objective represents the anticipated commercial outcome of the collaboration, which is derived from the corporate strategy and business opportunities. During supplier conversations, it helps to focus on an open communication and asking targeted questions about their innovation management and capacity. This allows concluding the capability as well as a willingness to cooperate. In conclusion, supplier collaboration can lead to a competitive advantage. Being the first to bring up a new product or service leads to a temporary competitive advantage. Nevertheless, supplier collaboration also inhabits a certain bias and dependency, which should always be on top of the mind. Are you about to initiate the first supplier collaboration or already have the first lessons learned? We are looking forward to an interesting exchange and discussions!

We would like to thank Felix Kesselberg for his contribution to this article.