How do you face urban congestion and rising service demands? Urban warehouses have the potential to reshape the logic how city centers operate.

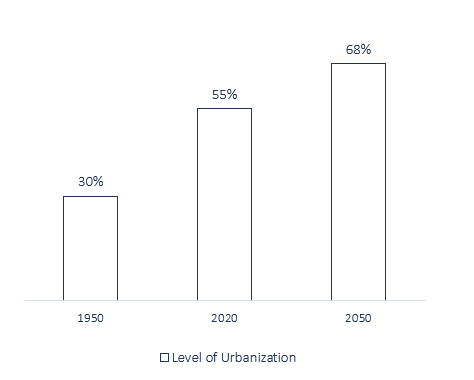

In the past decades we have witnessed a steady concentration of inhabitants in urban centers. Currently, around 55% of the global population is residing in urban areas. Although, North America presently has the highest rate, Asian and African cities are catching up fast and undergoing the most rapid shift.

As cities continue to grow, they also expand their dominant market position. It has become essential for companies to specifically focus on these areas and serve them with the demanded products and services. At the same time the expected service levels are drastically rising due to social media promotions and the high logistical emphasis of e-commerce. It has reached the point that consumers expect to receive a delivery within hours to placing the order or that products become personalized to the consumer’s taste.

Fulfilling these expectations is hard and requires a certain level of professionalism and organizational maturity. Frictionless processes, efficient systems and an agile network are necessary in order to achieve upcoming performance standards. Many companies are beginning to setup dedicated urban distribution solutions to meet customer requirements in these congested markets. One crucial puzzle piece in these solutions are urban warehouses.

Next to established retailers, also outsiders and startups are showing a growing interest in this “niche”. Several investment companies such as Blackstone are heavily devoting funds to commercial urban real estate around the world for warehouse and dark kitchen purposes. On the other side, a new breed of LSPs are manifesting to exclusively offer fast city logistics to a general customer base.

This blogpost highlights three best-in-class use cases of urban warehouse solutions and how they can provide a competitive advantage to your business.

1. Satellite warehouse

An urban satellite warehouse is the extended arm of a showroom, pop-up store or any shop that cannot host the necessary inhouse storage space. Limited available floor space or the maximization of the sales area are two main reasons to setup such an approach.

The primary role of a satellite warehouse is to replenish the stores. Due to its proximity this can happen multiple times a day or even on immediate demand. Additionally, value-added services such as repairs handling, small scale production/personalization or returns handling are possible to enhance the value proposition of the shop location. Another opportunity is process optimization. By shifting certain process steps to an outside location, the store can focus on its core capabilities – presenting and selling products.

The key challenge in operating this warehouse style is ensuring well-functioning and integrated processes. Due to the essential lifeline between the store and its warehouse any operational hiccup can bullwhip into costly inefficiencies, empty shelves or lost sales. However, not only replenishments need to be guaranteed. An interrupted waste disposal, returns handling or exchange of transport units (i.e. pallets, dollies or boxes) can quickly cause backlashes that accumulate within the sales area. All these activities are already difficult to handle in a regular environment. Several complications cause additional planning complexity. Stores may not be accessible all day long or lack a logistical infrastructure that enables fluid processes. A satellite warehouse can only function in a well-orchestrated supply chain.

2. Multi-site warehouse

Multi-site warehouses are a group of warehouses locations supplying overlapping geographical regions. These warehouses are managed as one, functionally inter-related but geographically disperse. Often cities do not provide the required square meters at one location to host the needed storage space. It might therefore be a compromise for planners. On the one hand a large enough facility is required and on the other hand proximity to the customers must be achieved.

The role of the warehouses is conventional, meaning replenish and relief stores or direct end-consumer delivery. However, the delivery-sourcing point relation is not as commonly 1:1 but 1:n. Already today, similar concepts can also be seen on a national or pan-regional scale. Here the primary goal is to create an agile sourcing structure and risk distribution that compensates potential inventory level mismatches (i.e. warehouse A does not have the needed product, but warehouse B does).

The key challenges of an urban multi-site solution are inventory and transport management. Will SKUs be exclusively stored at one location or kept in parallel at every site? Which products are commonly ordered in a bundle? Does each warehouse fulfill isolated services or not? Which warehouse fulfills an incoming order? Is a vehicle assigned to a specific location or can it dynamically switch? The process and planning complexity exponentially increases the more flexible the network is designed to act. A multi-site warehouse will typically require more organizational effort and demands a detail orientated implementation phase to cope with the additional complexity.

3. Fast fulfillment center

The sole purpose of fast fulfillment centers is to minimize delivery lead times and run an outstanding customer service. In order to enable this speed, lean processes, a fast-turning inventory and a geographical proximity is crucial.

Amazon’s Prime Now network is the best-known example of fast fulfillment centers. In certain areas Amazon even offers a one-hour delivery service of a trimmed product-portfolio. Although e-commerce might be the obvious beneficiary of such warehouses, brick-and mortar retailers can also profit of them. Shops might provide instant ownership to its customers, however they will not be able to display the large product range of an online store. Fast fulfillment centers could be the product portfolio extender and promote an immediate home delivery of anything not found in-store.

The key challenges of fast fulfillment centers are the initial real-estate identification and limited economies of scale. Finding the right location which is close to customers, has reliable inbound and outbound accessibility and sufficient capacity is not easy. The race for these sites is accelerating and already sponsors multi-story warehouses constructions to satisfy all search criteria. Due to the reduced SKU range, limited space and fast turnover these sites will not be able to compete on overall handling efficiency with traditionally larger warehouses. Relative logistics costs will inevitably be higher, which not every product margin can justify. A fast fulfillment center typically has a tight business case and needs to be carefully setup to provide the necessary additional revenue.

Outlook

Surely, other forms of urban warehouse solutions exist (e.g. traditionally operated warehouses, urban production storage), concepts can be overlapping/hybrids and further challenges need to be overcome which are not elaborated previously in detail. The illustrated use-cases present highlights of innovative and dedicated city logistic solutions. Identifying the right warehouse design, a positive business case and an efficient realization strategy for your business is highly complex and needs to consider additional dimensions.

We at CAMELOT are looking forward to support you at reaching the next step in customer fulfillment and improving your logistical capabilities. Feel free to contact us.

We would like to thank Roman Joachim Wisst and Jochen Thomas for their valuable contribution to this article.