Most of the companies establish MDM to aim for two key goals. One is to reach and sustain high data quality, second is to realize both in the most efficient way. In this endeavor, automation of maintenance activities is a key success factor. Automated activities can run at scale, do not required human intervention and produce reliable data 24/7. Due to this fact, data maintenance automation functionality has ever since been part of MDM applications.

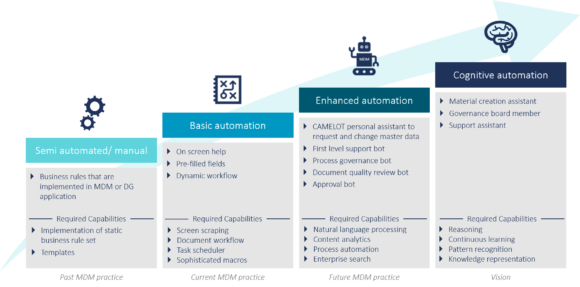

It all started with supporting semi-automated functionality that reduced the manual activities in the system. However, a user would still need to pick a task, review the data and complete the task for submission. The simplest examples for maintenance automation are derivation business rules that set a value based on conditions (e.g. if material type equals “Finished Product”, then set base unit to “Each”). Until today, such rules are implemented in a static manner by control tables and coding. Furthermore, the rules typically are defined in a joined effort by MDM and functional experts. This can be a very exhausting exercise, especially when several functions/ regions/ departments are involved, for shared data objects (e.g. material master). The fact that in most cases exceptions apply further complicates the exercise and the complexity of the technical implementation.

Over the course of the last 15-20 years the concepts have evolved, and the technical capabilities have improved, accordingly the level of automation has increased. In combination with complementary concepts like templates, scenarios etc. basic automation has proven to provide great value for the organizations. Still, most of the solution rely on “old” technology (e.g. coding and control tables). In order to achieve higher levels of automation and to be able to cover more complex tasks, it requires more sophisticated technical capabilities.

Fortunately, robotic process automation (RPA) can provide such capabilities for enhanced automation. RPA is not a technology, it is more an approach that bundles several technical capabilities e.g. screen scraping and natural language understanding. The new capabilities allow to provide support for the users (attended automation) or can independently perform tasks (unattended automation) that typically require human intervention. For example, reading an e-mail request, understanding what the requestor wants (intend), identifying the related master data (entities), and acting accordingly, is something that is done today by MDM teams. RPA provides capabilities to automate such steps with a high coverage of cases. Only in exceptional or rare cases an MDM expert is involved. Due to the capabilities, many companies see RPA as an enabler that allows a shift from shared service enabled data maintenance to bot enabled data maintenance.

Although RPA for MDM is innovative and only few companies are using it already, RPA for automation as such is already quite mature and there are already many solutions in the market (e.g. BluePrism, Automation Anywhere and UIpath) that can be leveraged to achieve the following benefits:

With recent breakthroughs in technology and (data) science, the capabilities have significantly improved. More complex scenarios can be covered, less human intervention is required, and the solutions can dynamically respond. Hence, state of the art RPA is not just about execution/ automation of single maintenance steps anymore. It’s about creating MDM (ro-)bots.

The vision for RPA in MDM results from that trend and we call it cognitive automation. By leveraging artificial intelligence capabilities (such as reasoning) and by applying concepts of machine learning, RPA solutions will be able to learn from experience. Also, they will have a good understanding of relevant context information (knowledge representation) that enables them to make the right decisions and to maintain data with high data quality. As a result, MDM manual maintenance activities will reduce to a minimum e.g. only setting particular process triggers.

CAMELOT supports RPA experienced and unexperienced customers with achieving their automation goals. Depending on the maturity the journey starts with first workshops, an initial Proof of Concept (3-5 months) or directly with the design and implementation of an enterprise solution.

We would like to thank Mirjam Baldas for her valuable contribution to this article.