Despite the ongoing digitalization hype, end-to-end supply planning models still struggle to be agile and responsive. In the last article, I outlined today’s state of supply planning, followed by an analysis of what is currently happening in these supply models. In this post, I will explain how this happens and why. I will also highlight the chance for a new end-to-end supply planning framework – one that connects all end-to-end planning processes, has single accountability, and is centrally controlled by supply parameters to ensure seamless product flow.

COVID-19 has challenged current supply chains in many aspects. From transport capacity shortages due to lockdowns or disruptions in goods traffic to changes in customer demand – the pandemic has shown the urgency to modernize supply planning towards more agility and resilience. Many of the existing supply planning frameworks struggle to achieve basic objectives like:

- Central & regional control of target service level fulfilment

- Stabilization of manufacturing assets to reduce upstream variability

- Stable supply signals to optimize component supply and inventories that reduce the bullwhip effect

- Improvement of COGS (costs of goods sold) along connected supply nodes

- Tactical control of a supply chain’s service capabilities

How do these inefficiencies take place in supply planning and why is this happening along the supply chain?

Despite many inefficiencies along the supply chain, today’s supply planning operating models are often controlled and driven by aggregated rough-cut/master plans. Central functions struggle to gain transparency on the supply capability such as visibility of inventory positions in real-time, capacity profiles, etc. These would serve to evaluate tactical performance metrics such as inventory costs and service level targets in a sales and operations planning process.

Traditional shortcomings

Conceptually, in supply planning not much has changed for the last years despite costly process refinements, process-oriented organizations, and implementations of advanced planning technology. Material requirements planning (MRP) still propagates demand and routes it across the supplying nodes not reflecting the true supply capabilities tactically. The results are often operational emergencies and protectionism of short-term plans.

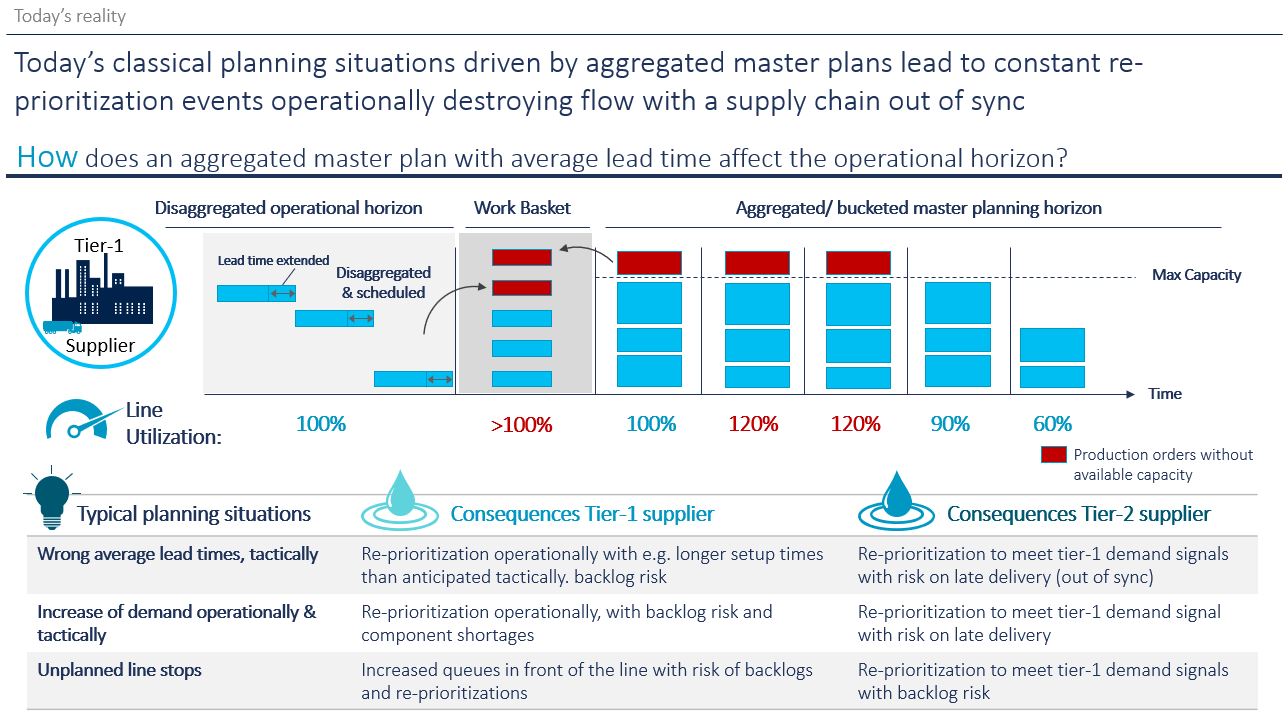

It is interesting that supply chain professionals still refer to a tactical plan as rough-cut plan or master plan. It might seem correct that aggregated tactical plans based on average lead times are sufficient to gain visibility on available and required capacity and materials to reduce complexity. However, it poses quite a challenge to determine appropriate average lead times to reflect an appropriate material and capacity constraint plan. Observations have shown for instance that in manufacturing environments with intensive changeovers the actual setup-dependent changeover time often exceeds the average setup time by up to 50%.

Thus, assuming the wrong average lead times in combination with aggregated or bucketed capacity, supply plans have a significant impact end-to-end. Along the supply nodes, period by period a plan may seem sufficient. However, once it is rolling into the operational horizon, the disaggregation of a plan required to schedule a factory can have significant lead time effects. These lead time effects are often driven by changeover times, commercial customer prioritizations, operational inefficiency, etc.

A vicious circle

Suddenly, what seemed to be feasible and in sync tactically, is not any more so on an operational level. An aggregated, bucketed master plan for instance may assume the average machine setup time for a particular product or product portfolio. Once the aggregated plan transitions into the operational time horizon, a master plan becomes disaggregated into a production schedule. To protect the operational plan, the tactical plan is often separated by a work in process basket where prioritized orders are pulled into the operational horizon by a planner/ scheduler or from the operational zone back into the work in process basket, again because of re-prioritizations. This work basket is in many industries characterized by a bow wave at the end of the operational period, the freeze period. The disaggregation is reflected by scheduling with detailed start and end times and actual setup times based on the predecessor-successor product relationships. Also, customer prioritizations due to short-term demand changes become predominant. In the end, the order lead time increases. This often leads to a situation where the capacity in the operational horizon is not sufficient, and a re-prioritization of the production orders is initiated.

This starts a vicious circle. While a tactical plan is re-created based on its MRP planning frequency, an operational plan becomes completely decoupled from its tactical horizon. The short-term operational horizon is now characterized by constant re-prioritization based on “first come – first serve”, as well as component, machine, and labor availability. In a short-term perspective it seems that the available capacity is not enough to fulfill the demand. Constant changes on a manufacturing line lead to line availability issues. Capacity availability becomes a challenge. From an end-to-end supply planning point-of-view, functional silos are created supply node by supply node, with constant firefighting as a result.

Increased buffers

Short-term changes of a schedule lead to noise and variability along the supplying nodes. This is caused by re-planning/re-scheduling of a nodes plan to accommodate changes in the demand situation. The operational planning window gets tight capacity-wise, backlogs occur, orders are waiting and queuing outside the operational fulfilment horizon. Operational plan stability becomes a necessity, but this is often realized by an operational protectionism, by artificially firming plans. Tactical and operational plans become two entities where the rough cut/master plan stops to be feasible. End-to-end plans get out of sync and key components are short, which further interrupts production and leads to re-planning affecting the tactical horizon. As a result, lead time buffers, capacity buffers or inventory buffers are increased to keep service level targets, which negatively affects costs of goods sold (COGS).

Let’s face reality

In summary, in today’s supply models the supply capabilities are not adequately reflected leading to supply variations and service level violations. Aggregated and bucketed master plans with difficult-to-determine average lead times promote the bullwhip effect. Observations have shown that lead times can vary from a tactical to an operational plan by up to 50% on individual order level. A master plan is not able to lay out a synchronized material flow constrained by available capacity into the future because the short-term events constantly bring a plan out of sync.

Limited organizational supply planning capabilities without local and global end-to-end accountabilities lead to infeasible and misaligned supply plans. Today’s rough-cut master plans are not designed to parameterize a supply plan end-to-end by constantly calibrating inventory buffers to stabilize manufacturing. As a consequence, the organizational supply planning operating models are not enabled to calibrate a supply chain centrally by using supply planning parameters. Tactical rough-cut or master planning become not only functionally two entities but also organizationally. Local sites tend to evade into a shadow planning in spreadsheets escaping from the instability that an MRP based plan entails.

This deteriorates the reliability and visibility of a supply plan end-to-end even further. It is not unusual for these types of environments that tactical planning capabilities of local and global organizations also deteriorate because of the lack of credibility of a tactical supply chain plan. This happens because supply shortfalls such as material and capacity constraints are not adequately considered by MRP-driven master plans leading to over or understating the supply capabilities across the supply chain.

Have you experienced similar? Please let me know how operational and tactical planning works in your company.

Part 1: What’s happening in today’s supply planning models? – CAMELOT Blog (camelot-group.com)