During the last years we have mainly worked on projects in production planning. Now we would like to share some personal highlights of hidden potentials. Hidden because they might not be obvious, or even though they are supposed to be obvious, they are just not lived and might be worth to be brought back on the table (Part II Rough-cut planning).

Living in the digital age of AI, predictive analytics, robotics, it is surprising how many companies are not exploiting their potentials when it comes to production planning. We have already highlighted in one of my previous articles why production planning might get lost on the way to digital wonderland. Now we would like to draw on one of the consequences and indicate the improvement potential.

Planning disregarding any production scheduling logic

As amazing as it sounds, many companies are still executing rough-cut planning on an aggregated level disregarding any production scheduling logic or optimal product sequence. The result is a rough-cut production plan for which the capacity situation is either over- or underestimated. This has a major impact on industries with high degree of sequence dependent changeover times in which the sequence of orders does matter and changeover times can consume multiple shifts.

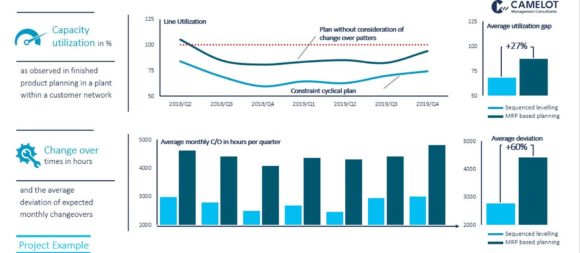

Figure 1: From a rough-cut plan based on MRP (Material Requirements Planning) to a optimized production plan

Within one of our last projects we compared the result of a rough-cut plan based on MRP (Material Requirements Planning) to a changeover optimized production plan. The results have been an average overestimation of monthly capacity utilization by 27% and a deviation from actual changeover times of 60% on average over a period of two years.

Lost sales and bullwhip effect

The impacts we see with pure rough-cut production planning are the following, to name only a few:

- Lost sales:declined sales, because you think you cannot manage more sales; or even worse acceptance of additional sales opportunities without ever having the capacity to do so

- Synchronization issues:a relaxed capacity situation in tactical horizon might result in firefighting situations in operational horizon and in additional chaos upstream the supply chain

- Increased variability & bullwhip effect: Mainly caused by translating a simplified rough-cut plan into a detailed production plan with all constraints considered

“It is better to be roughly right than precisely wrong” J.M. Keynes

While we agree with Keynes opinion on rather being approximately right than precisely wrong, the key part for me is to be at least on the “right” track. We do not support full automation and optimization to the very last bit. But please…We should be able to do better than pure MRP based rough-cut planning. It is from 1950…

Hidden potentials in production planning: Part I Contradictions

Why production planning might get lost on the way to digital wonderland