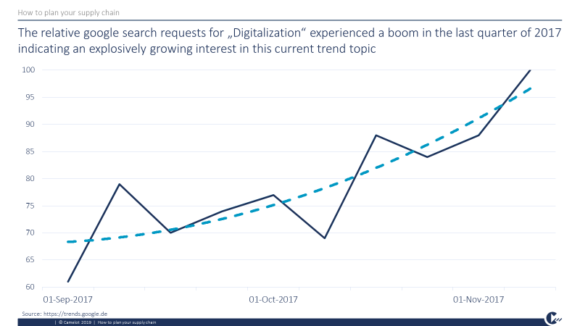

Within the last quarter of 2017 the number of Google searches for digitalization increased by more than 60%, which clearly shows the interest across industries. So what does digitalization mean for supply chain planning? In a small series of articles, we want to outline the key characteristics of optimization-based and heuristic-based approaches for the field of automated supply chain planning.

Let’s start by looking at the underlying principles of the two approaches.

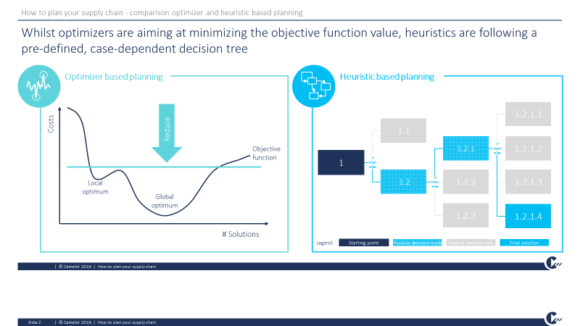

Optimization-based planning and scheduling in a nutshell means determining a mathematically proven optimal solution for a specific planning scenario modeled as a more or less complex system of mathematical equations. This requires the formulation of both – the planning target and the limiting conditions – according to the characteristics of the supply chain in terms of mathematical variables and constants. Expressing the planning objective mostly means the introduction of a total cost function whose value is to be minimized. Exemplary constraints may include scarce resource capacities or component/raw material availability. The art of modeling the so called objective function and constraints of an optimization model leaves wide-ranging degrees of freedom to finally identify a suitable model formulation which very often requires expert knowledge. Depending on the declaration of decision variables representing the solution, also the granularity of the data needed is defined. Solving the model to optimality is usually achieved by using an optimization engine where most of the high-performance solvers are provided by commercial software vendors. The application of commercial solvers is based on highly-sophisticated optimization algorithms and usually acts as a black-box process for practitioners who evaluate and analyze the results. Besides this pure optimization approach for supply chain planning tasks, huge efforts have been made in the field of operations research to develop hybrid methods combining mathematical optimization and heuristic planning.

The scheme is always the same

But what is heuristic planning? Wikipedia defines a heuristic as “strategies derived from previous experiences with similar problems…” – which means? It is basically a defined path of logical decisions for a given problem. Heuristics in supply chain planning consider the given planning situation including the available transactional- and master data and execute predefined steps controlled by the available information. The simplest “heuristic” in supply chain planning is therefore an MRP. The scheme is always the same. Follow the timeline per product until requirements are not covered by supply – place an order according to lot size settings and explode the bill of material. Then continue with the next product. More sophisticated planning and scheduling heuristics on the other hand are considering up to hundreds of possibilities until an order is finally placed including consideration of capacity requirements, material availability and supply chain strategy definitions (see https://www.camelot-mc.com/en/next-level-production-planning/ for an example of a sophisticated heuristic). This is therefore one of the main arguments that is often brought up for heuristics. I can tell it what to consider and I can check afterwards whether and how it has considered these definitions. So, would a heuristic be your ideal choice since you can codify your ideal supply chain configuration?

Keeping this key characteristic of heuristics in mind and comparing it to the black-box-generic-mathematical-solver approach you might already have a first guess on the possibilities both approaches offer and the challenges that come along with it. Within our series we will outline the main differentiators to give you insights for a well-informed decision.

The objective is clear: getting the best results out of planning your supply chain (increasing service level, rightsizing inventories and increasing production line availability).

Part II: How to plan your supply chain

Part III: How to plan your supply chain

We thank Jens Rieder for his valuable contribution to this article.